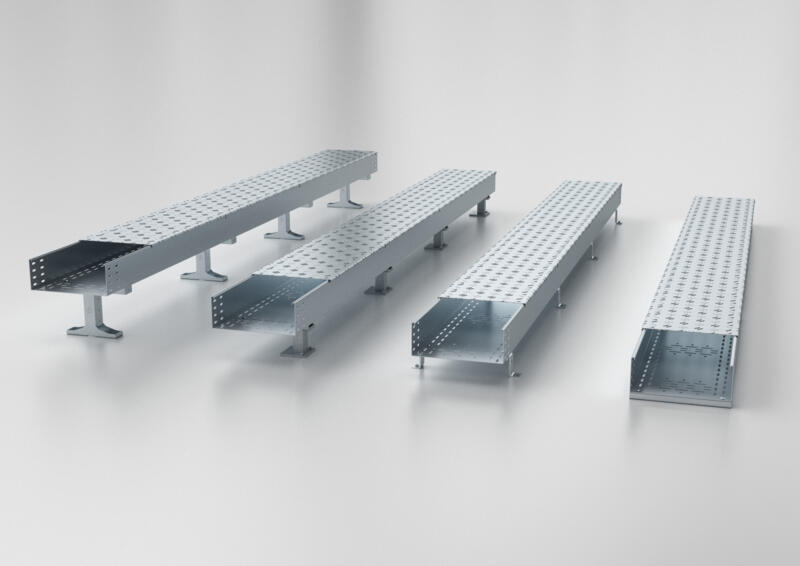

Protection at every turn with the BKRS system

Slip protection and displacement area

The slip and step protection of the covers is immensely important for safe working on walkable cable trays. The newly developed chequer plate arrangement of the BKRS covers ensures stability through optimum slip protection, minimising the risk of accidents in daily use.

Do you have any questions on this topic?

We’ll be glad to help!

What classification is required?

The required classification is dependent on the place the cover is used and is described in BGR 181 “Floors in working areas with slippage risk” and ASR A1.5/1.2 “Technical rules for workplaces”. The slip prevention of the covering surface is tested DIN 51130 “Testing of floor coverings – Determination of the anti-slip property” with the ramp test walking method. Here, the slip prevention is tested on a ramp with different angles of inclination from 6° to < 35° and assigned according to the evaluation groups R9 (lowest requirements) to R13 (highest requirements).

Tested anti-slip properties

The DBKR chequer plate cover fulfils the requirements of BGR and ASR and, with its certified anti-slip properties, it is suitable for most environments that are walked on and have a risk of slipping.

Displacement area for extreme soiling

If, due to the use of the building, extreme soiling with slippery substances (e.g. oils, animal fats, etc.) is to be expected, the surface must provide an appropriate displacement area for those substances in order to ensure that walking on the surface is safe. The specification is done using the designation “V” in connection with the index for the minimum volume of the displacement area. Here, the scale ranges from V4 (displacement volume: 4 cm3/dm2) to V10 (displacement volume: 10 cm3/dm2).

Good to know: Most industries require at least V4. With the valuation group of V10, the BKRS chequer plate cover far exceeds this requirement.

Benefits of the BKRS chequer plate cover at a glance

- Safe, anti-slip entry and exit due to corrugation on the cover and cover edges

- Certified anti-slip class R11

- Certified displacement space class V10

Product highlights

You might also find this interesting

Automotive: Electrical installation in chassis construction

In the automotive sector, OBO concentrates mainly on system construction and conveyor technology. Our focus is on chassis construction.

Maximum load-bearing capacity

Heavy loads, footsteps, dirt, dust – the BKRS system can handle all of this and more thanks to its ingenious system design. Cables are protected from damage.

Cover fastening

The cover is fastened quickly and easily, either with a turn buckle or with the cover clamps designed specifically for the chequer plate cover of the BKRS system.

Duct stand-off

OBO is listed by all standard automotive manufacturers. To meet the wide-ranging needs, we offer an approved duct stand-off solution for each of these manufacturers.

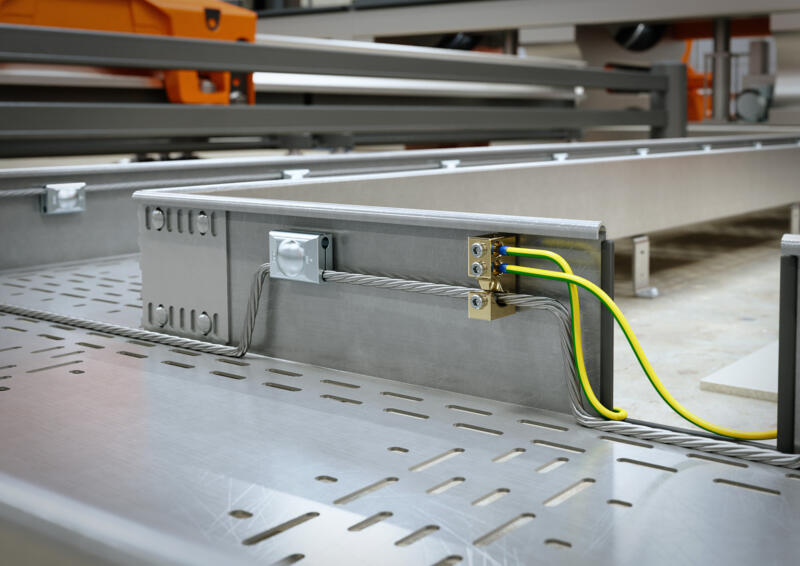

EMC protection and dust protection

Modern industrial environments present a major risk to sensitive cables. The BKRS system provides protection, offering an enclosed installation space.

Equipotential bonding

The BKRS system can be quickly and easily integrated in the equipotential bonding. Four different options are available for this.

Comprehensive accessories

A wide variety for every requirement: An extensive range of accessories for the BKRS cable trays rounds off the portfolio, offering numerous mounting benefits.