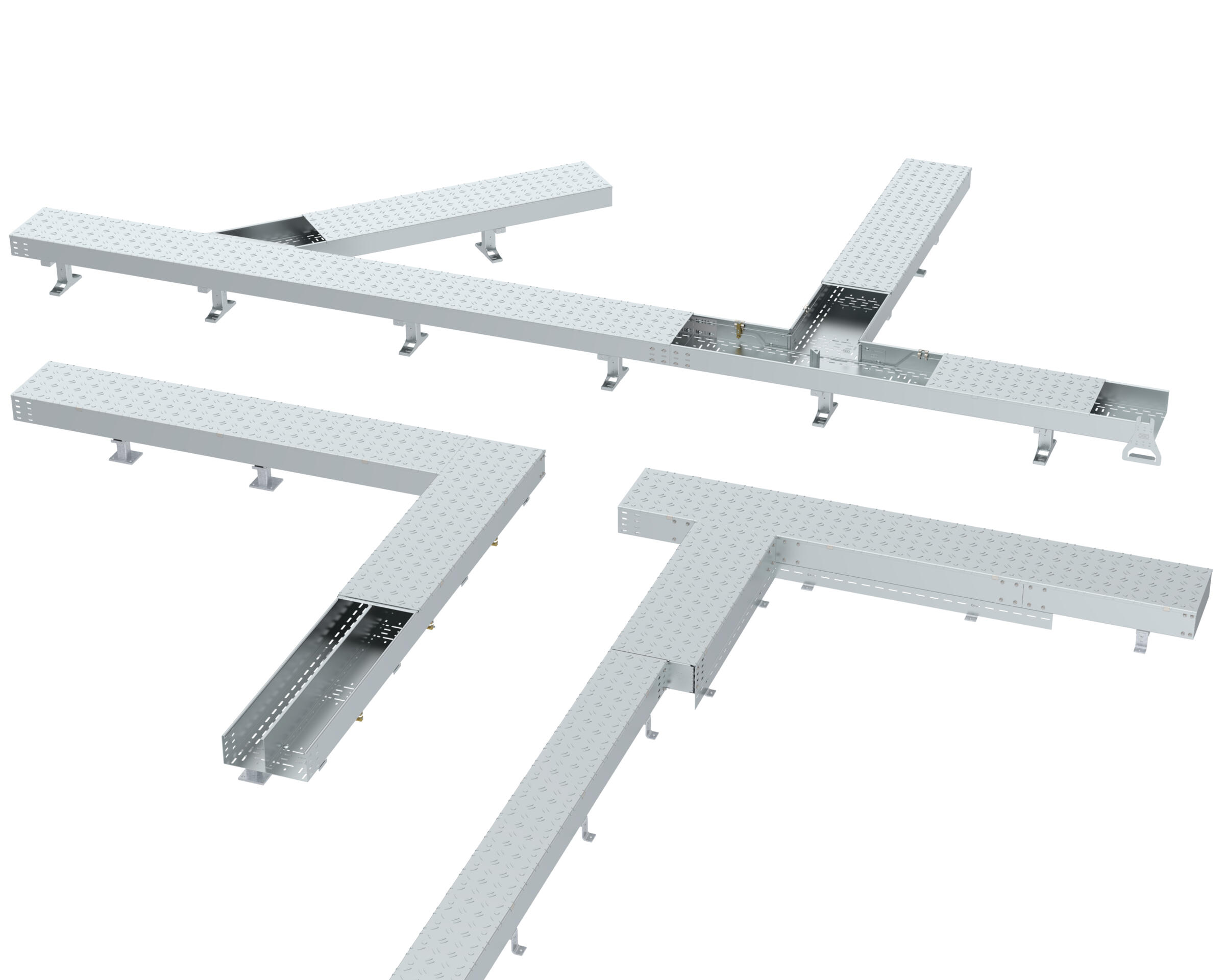

Electrical installation solutions in walkable cable tray systems

Effective protection of power supply cables and people in industry

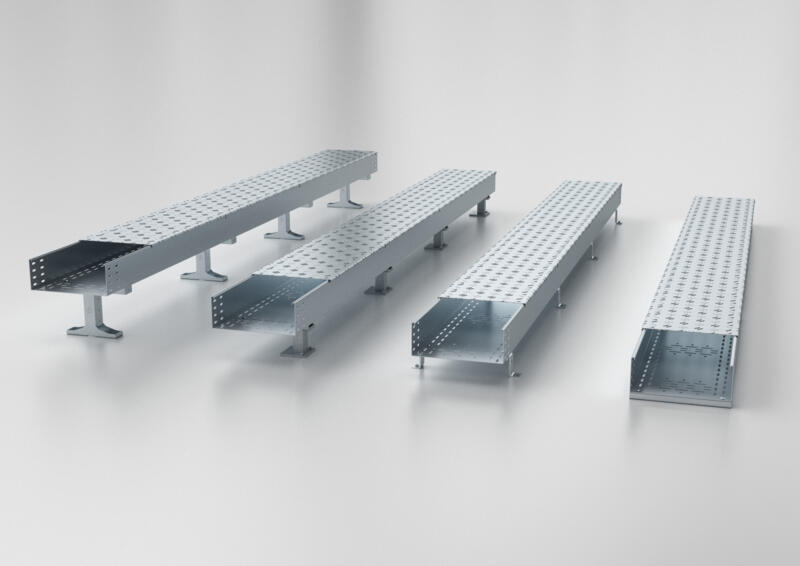

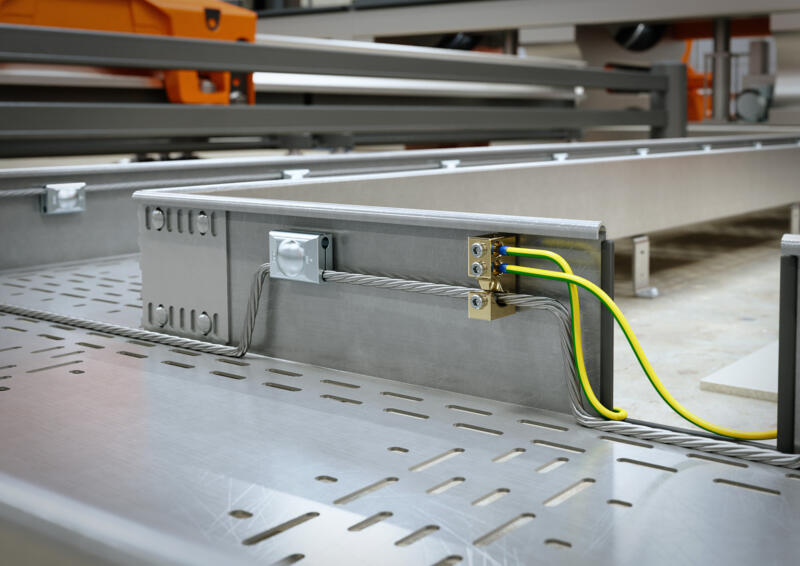

In the automotive sector, OBO concentrates mainly on system construction and conveyor technology. Our focus is on chassis construction, meaning the wiring of machines or systems along the production lines. The electrical installation in chassis construction covers 75% of the overall installation. Powerful protection against footfall, dust and many other loads is essential for supplying the systems with power and data reliably. To meet these requirements, OBO offers the BKRS walkable cable tray system. The system is designed for the highest loads, which frequently occur in the vicinity of machines and automated production systems with robotic elements.

Do you have any questions on this topic?

We’ll be glad to help!

The BKRS system offers the automotive industry these benefits

- The BKRS system is already appreciated by numerous giants of the automotive industry and has been approved in the factory standards of BMW Group, Volkswagen AG, Volvo Car Corporations, Jaguar Land Rover Ltd., Mercedes-Benz Group and Ford

- The dimensions and materials mean that they satisfy the guidelines and requirements of numerous other industries.

- UL-certified NEMA VE1

- Effective protection for energy, power and data supply in automated production lines and system construction applications

- Available with the side heights 100 and 110 mm

- With six widths between 100 and 600 mm available, there is a suitable cable tray system for every possible application

A system only a complete provider can deliver:

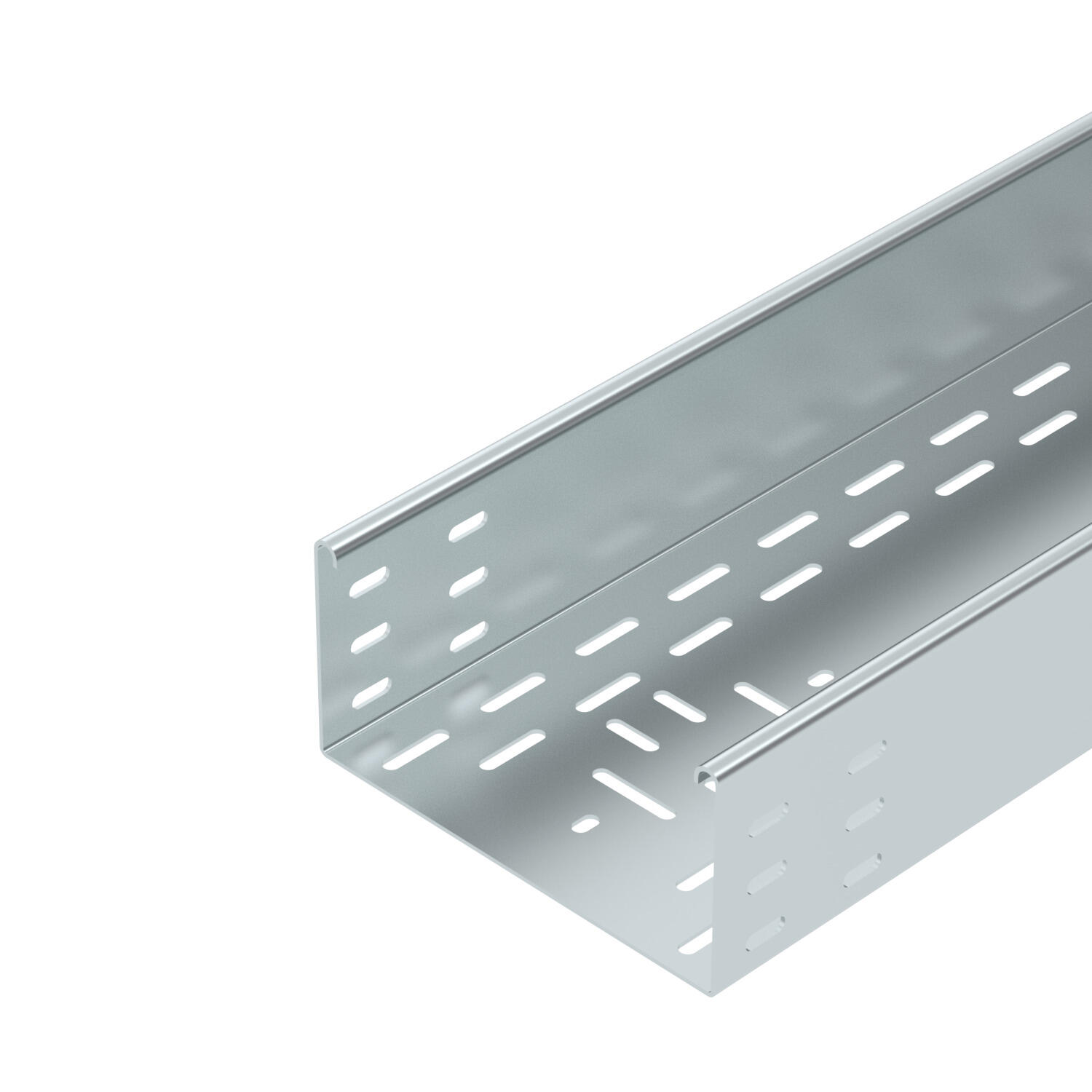

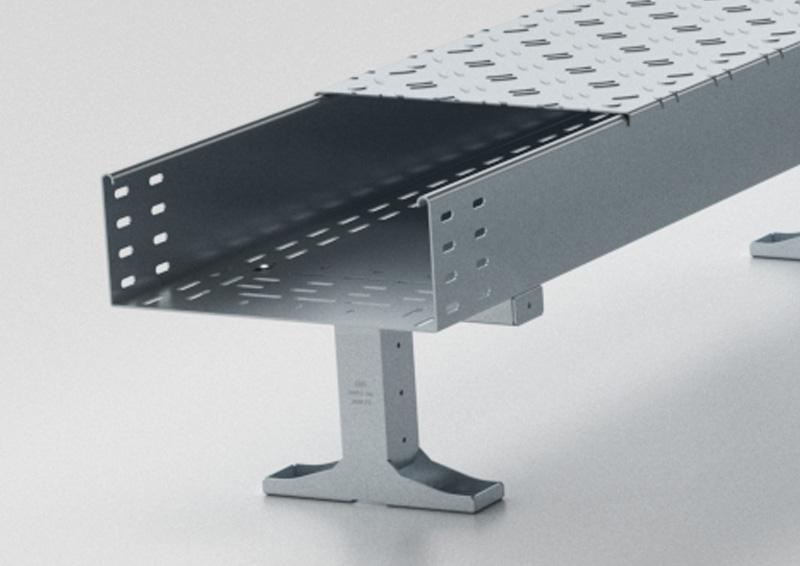

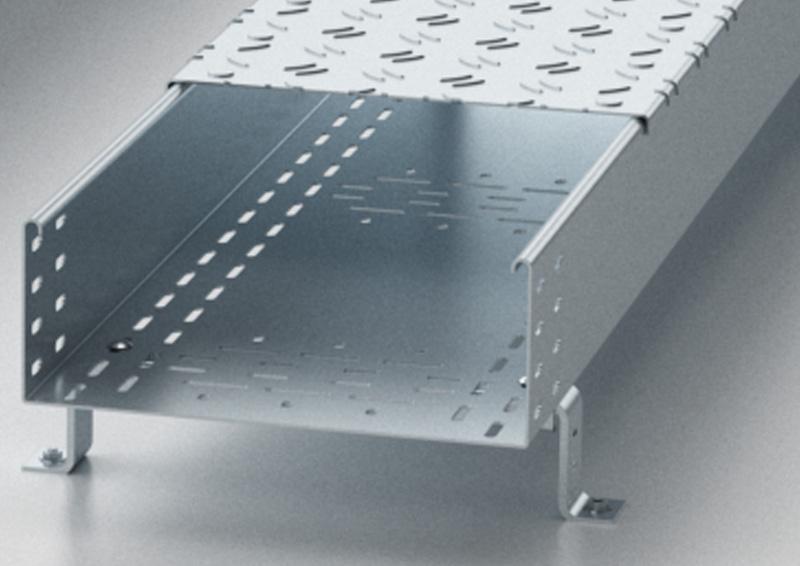

BKRS cable tray

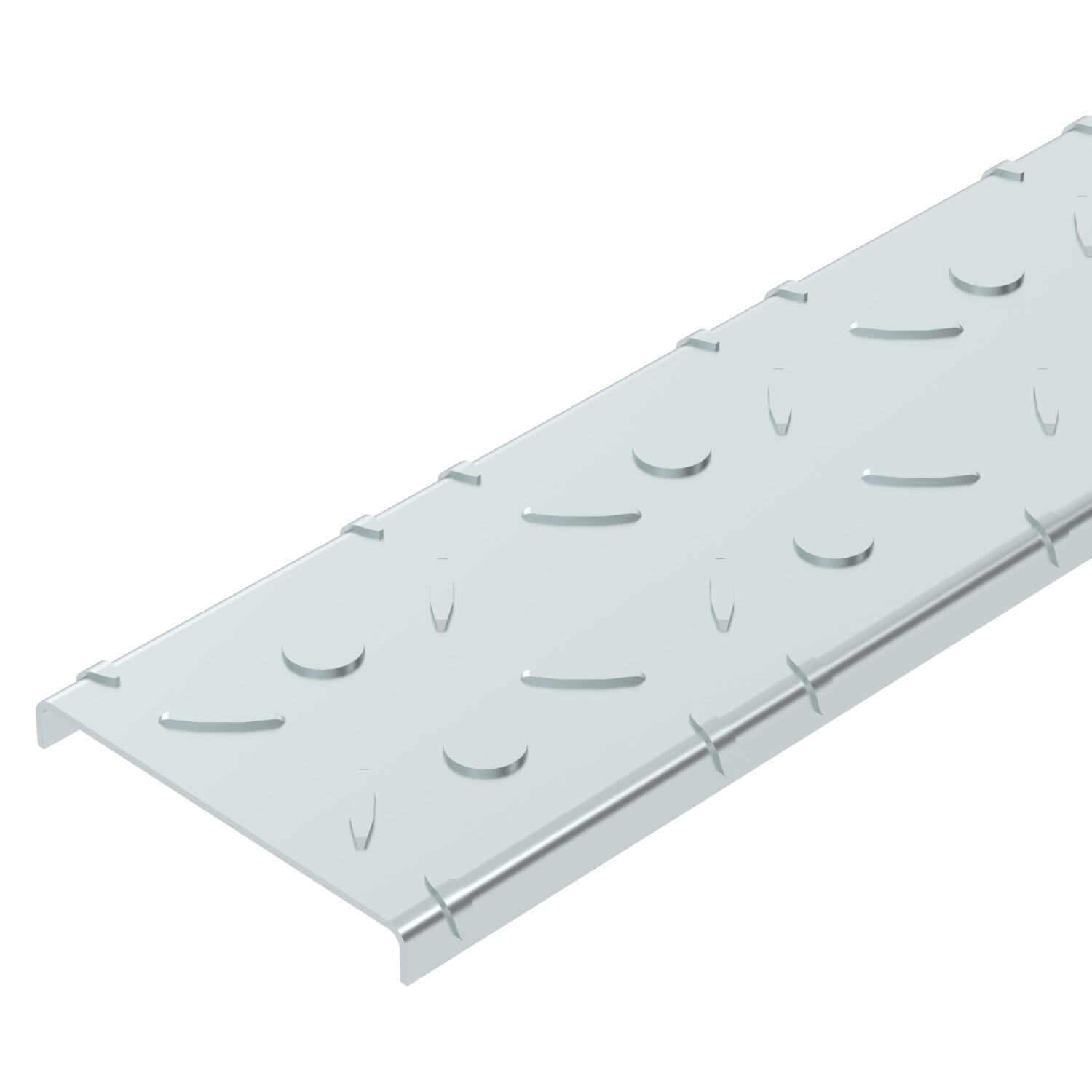

Chequer plate cover

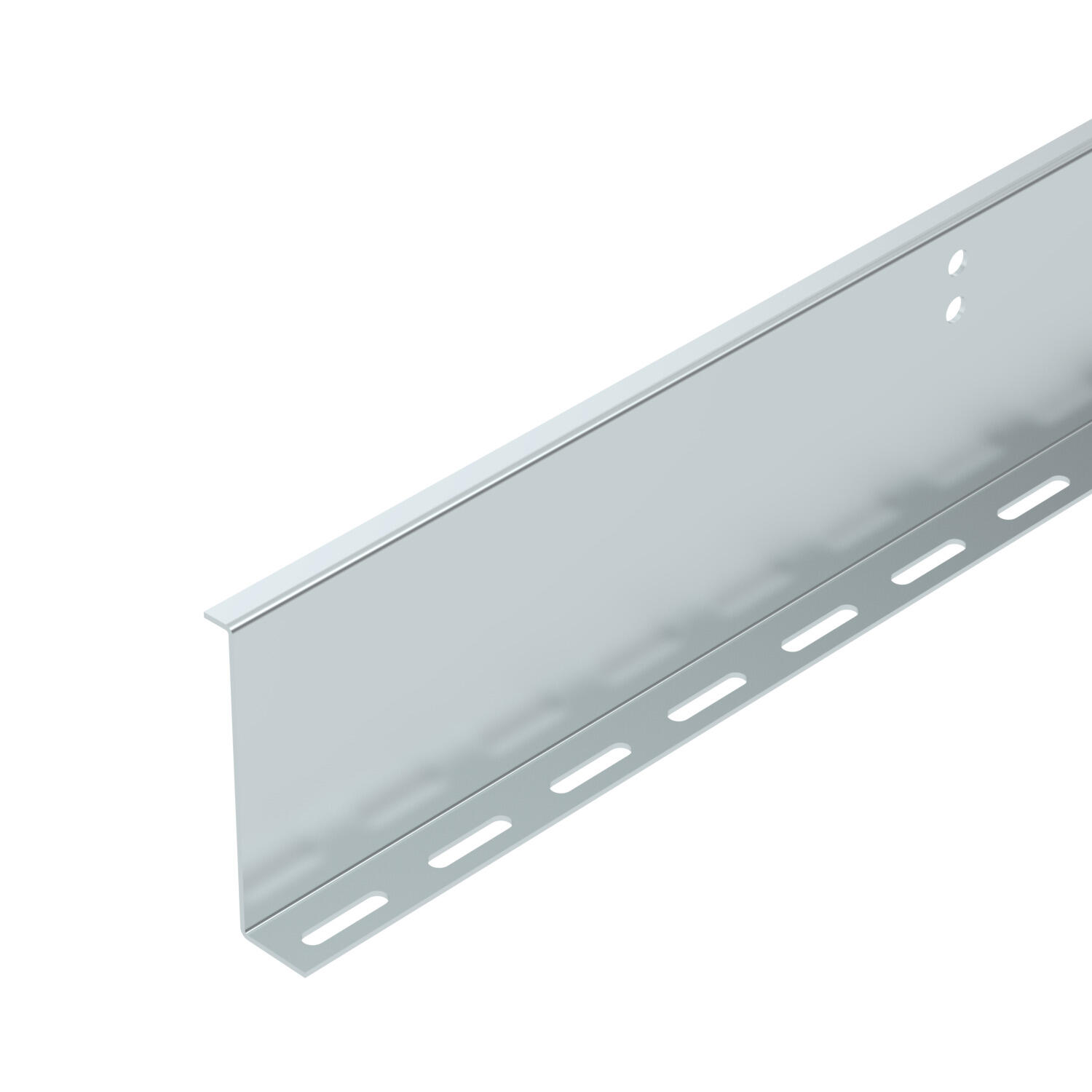

Dust protection element

Cover support

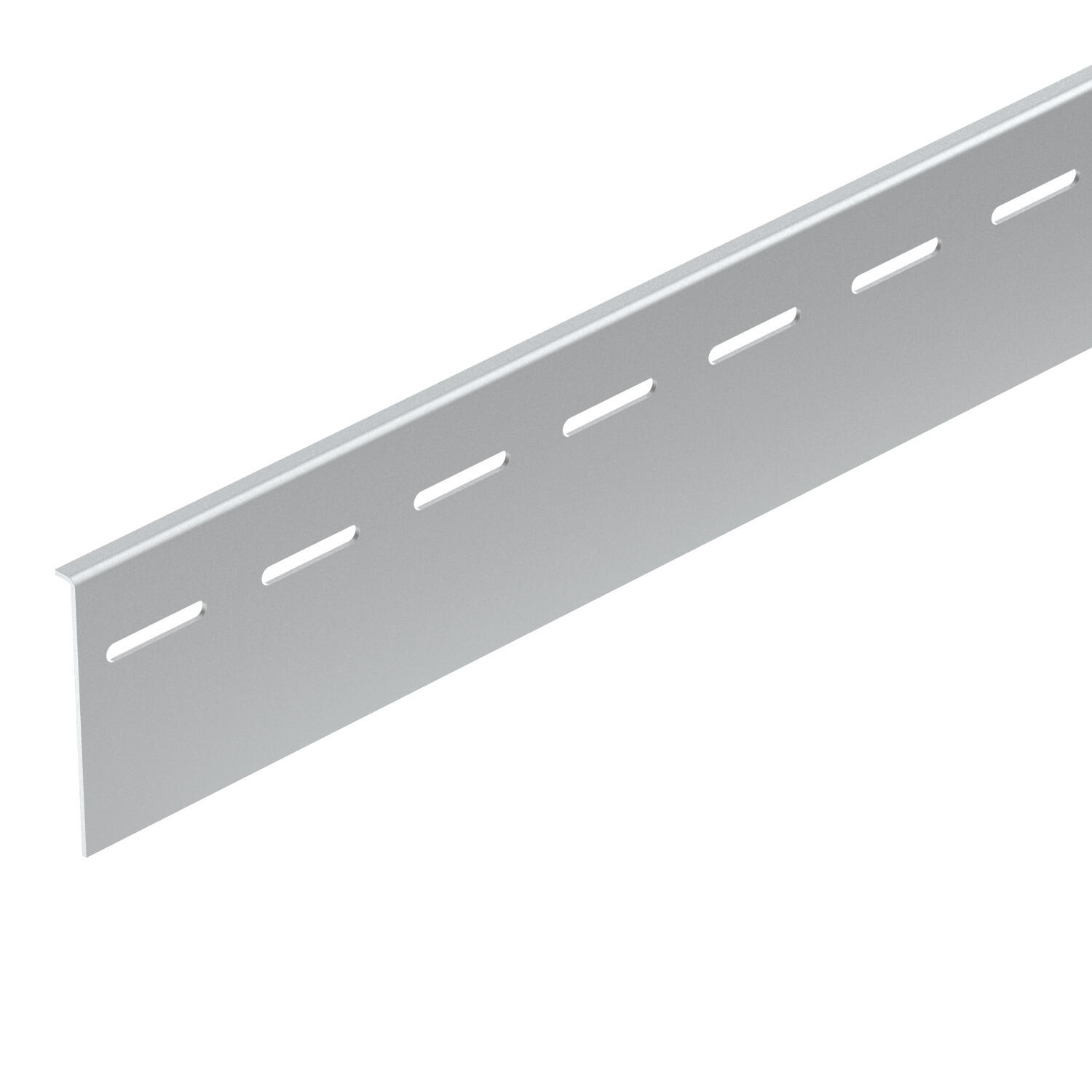

Z-shaped barrier strip

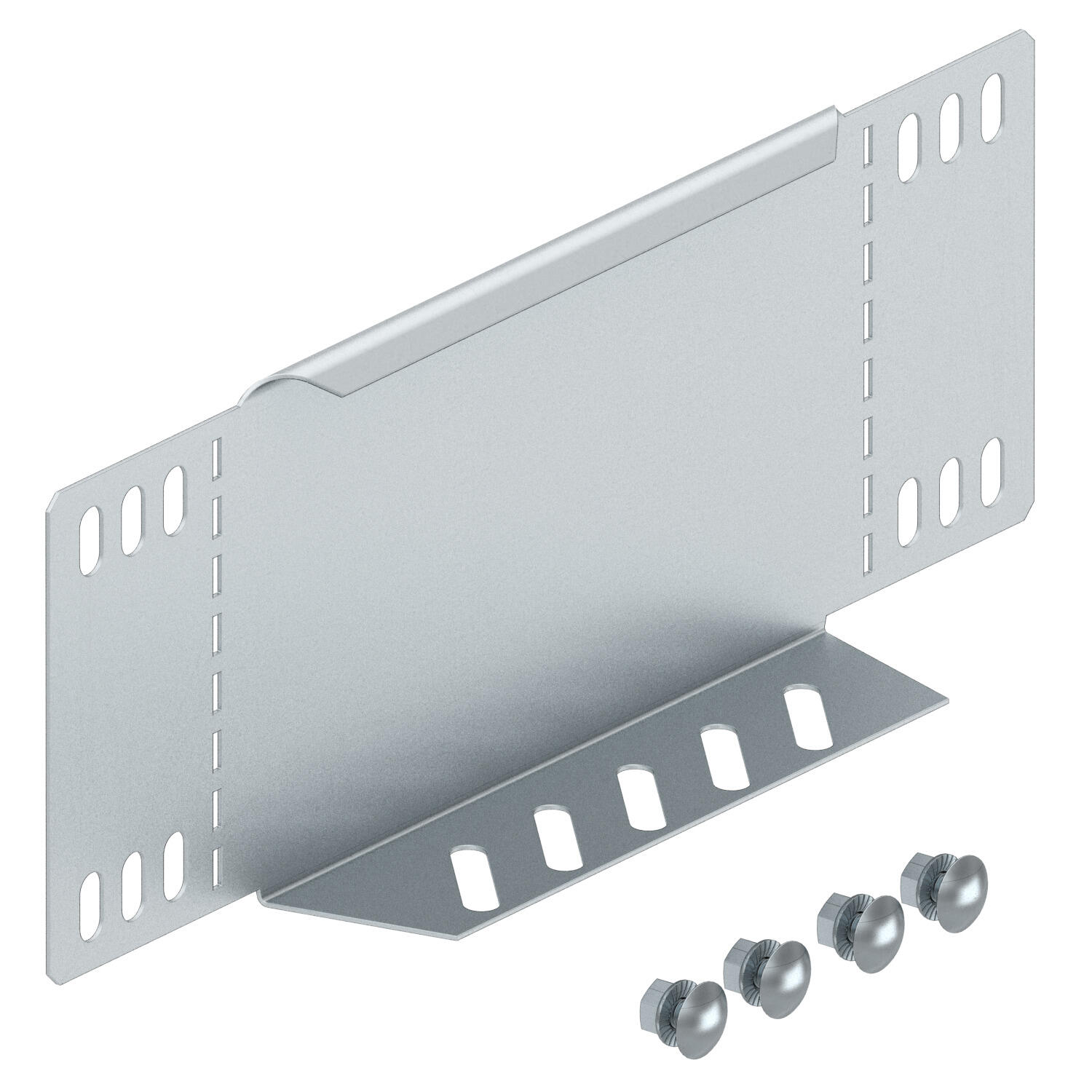

Reducer/stop-end

Symmetrical floor support

Support bracket

Z support and cross-beam for Z support

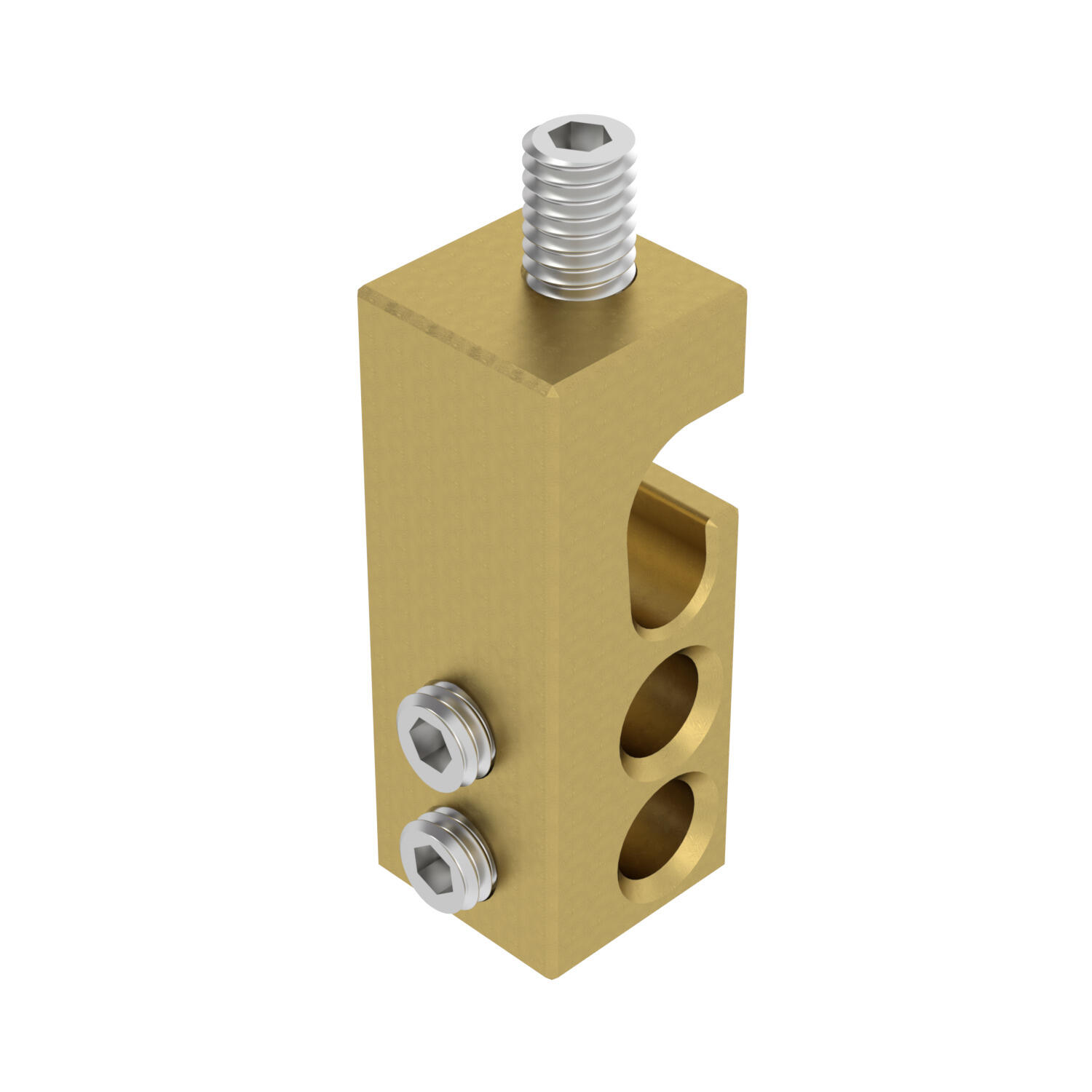

Connection terminal below the system

Protective panel for Z support

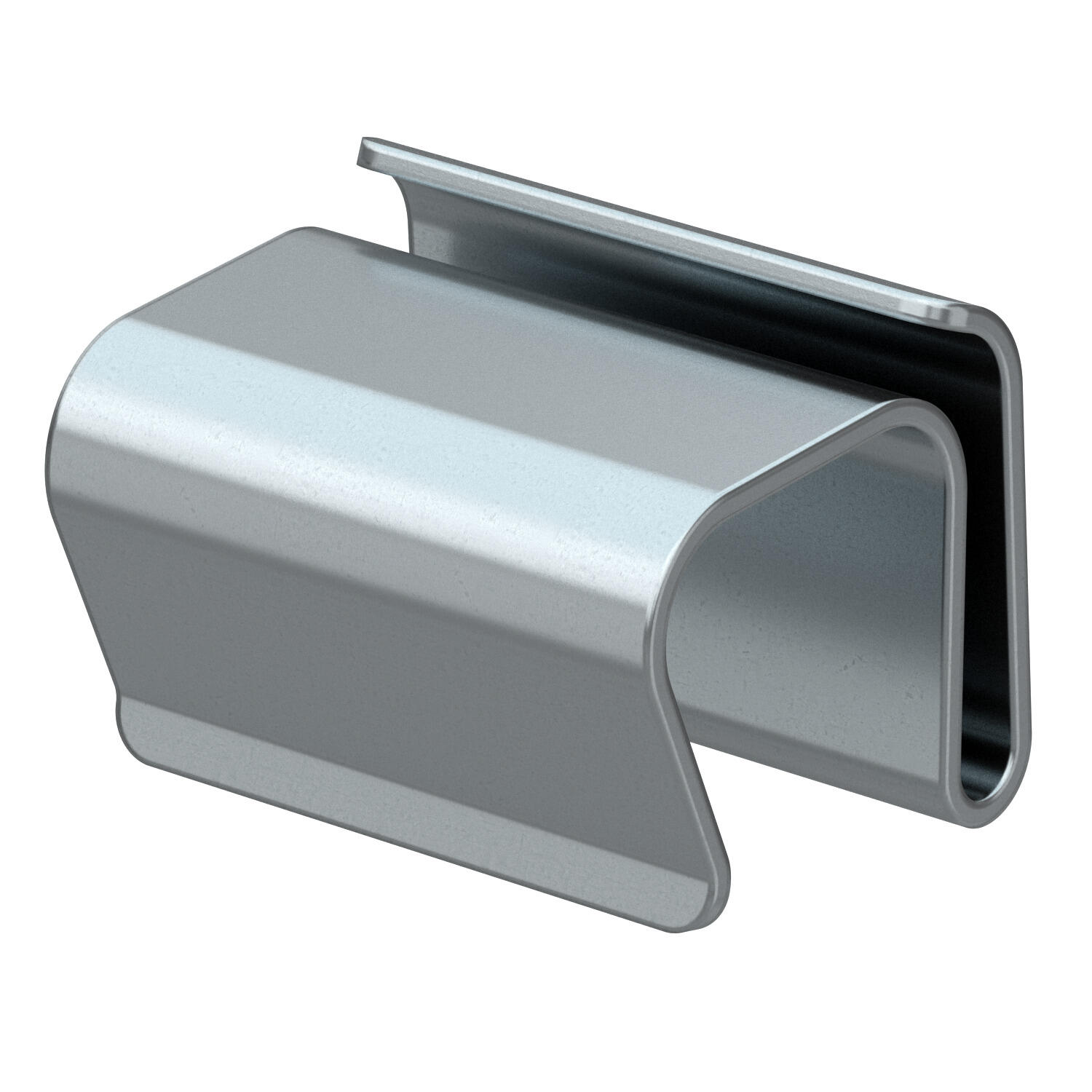

Cover clamp

Cover lifter

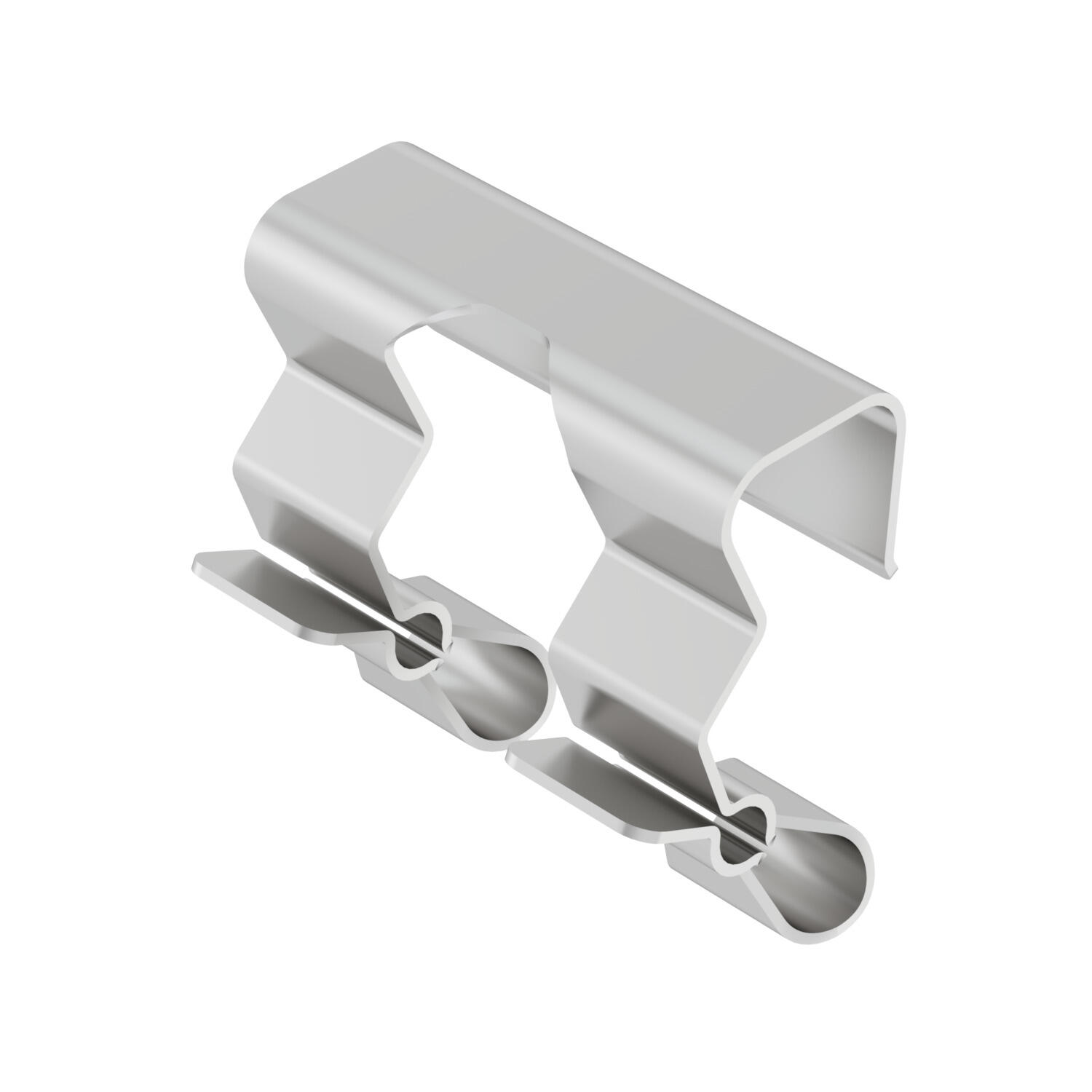

Clamp spring for conductor cable and connection terminal

Variable dust protection element

These product features provide stability in the automotive industry:

FAQ

What exactly are walkable cable tray systems?

What applications are OBO cable tray systems used for in the automotive industry?

What benefits are offered by OBO walkable cable trays?

Can the systems be customised?

Do OBO cable tray systems correspond to defined standards?

What sustainability aspects does OBO take into account in production?

What automotive manufacturers does OBO already work with?