Easily integrate walkable cable trays in the equipotential bonding

Implementing equipotential bonding with the BKRS system

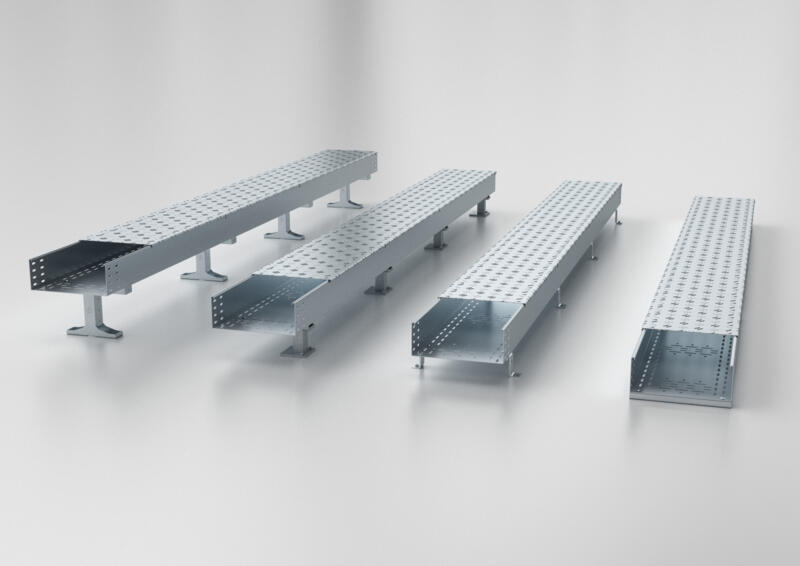

The BKRS walkable cable tray system can be quickly and easily integrated in the equipotential bonding. Four different options are available for this, making it possible to choose the one that best suits the installation conditions and environment.

Do you have any questions on this topic?

We’ll be glad to help!

The different options for inclusion in equipotential bonding at a glance

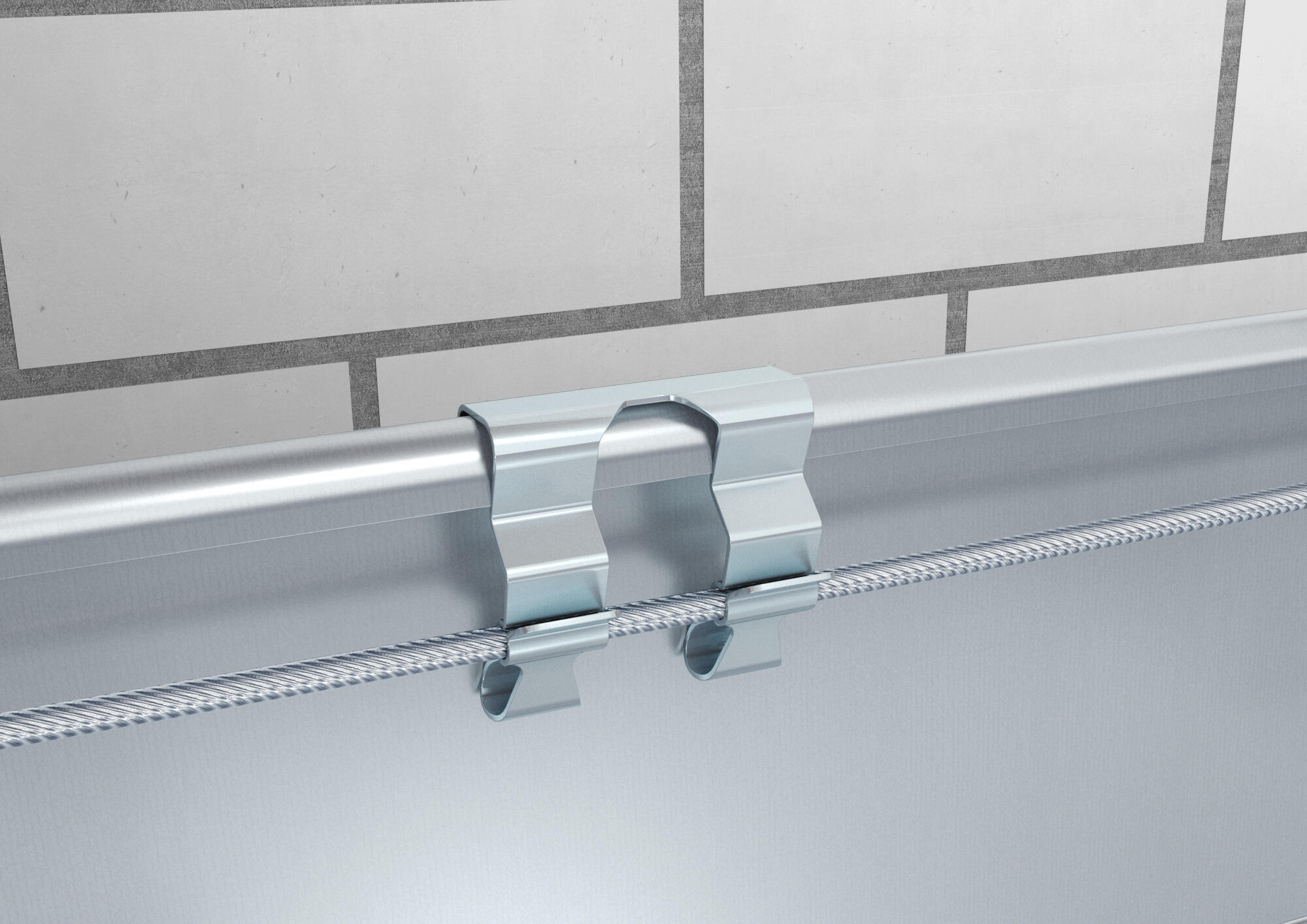

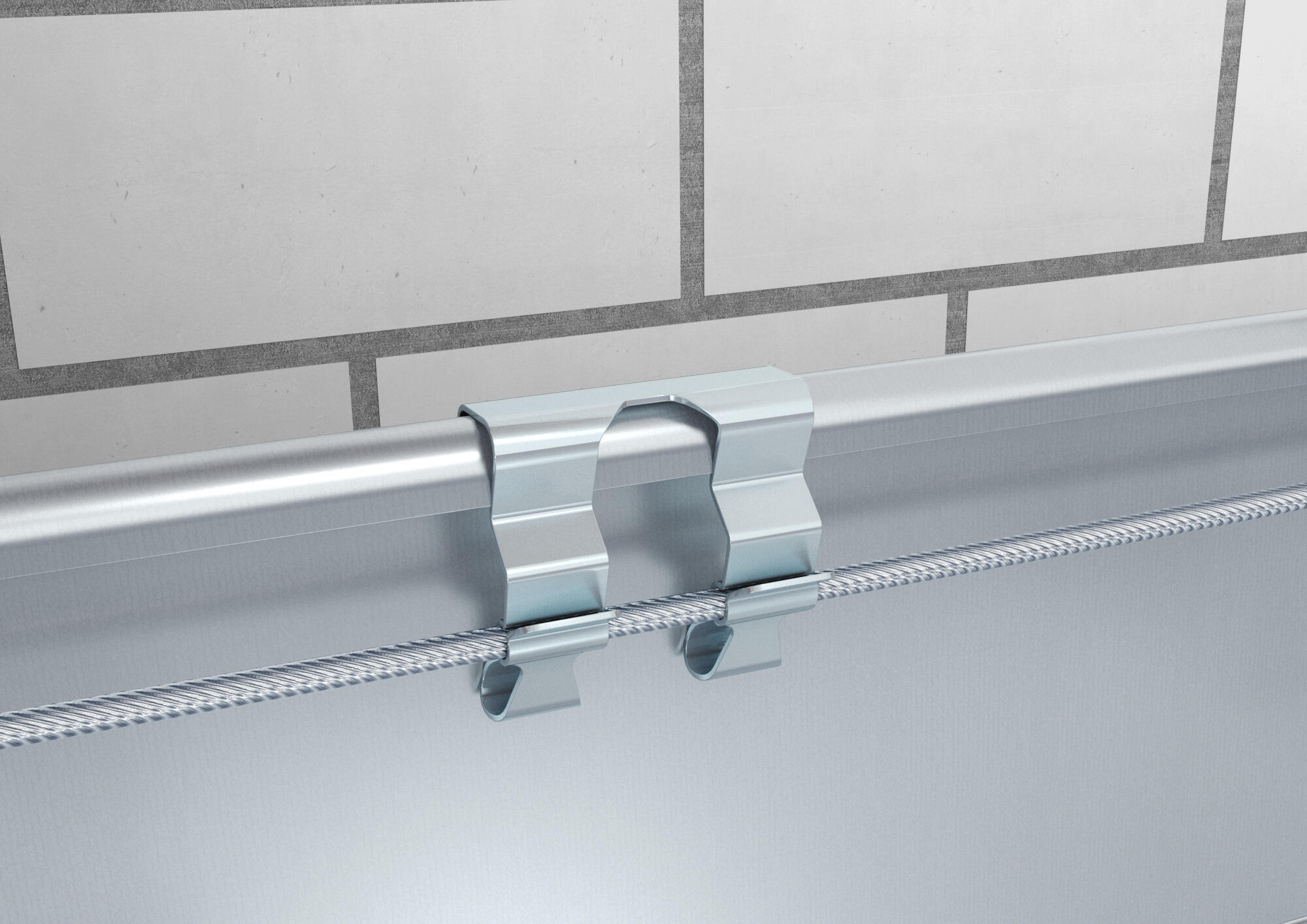

Option 1: End-to-end equipotential bonding in the cable tray profile

A continuous tin-plated copper cable is guided directly in the cable tray profile and fixed using the clamp spring. Installation is easy, done without tools or any additional drill holes – ideal for quick and clean integration into existing systems. Contacting can be established quickly, as the copper cable is inserted directly into the clamping spring.

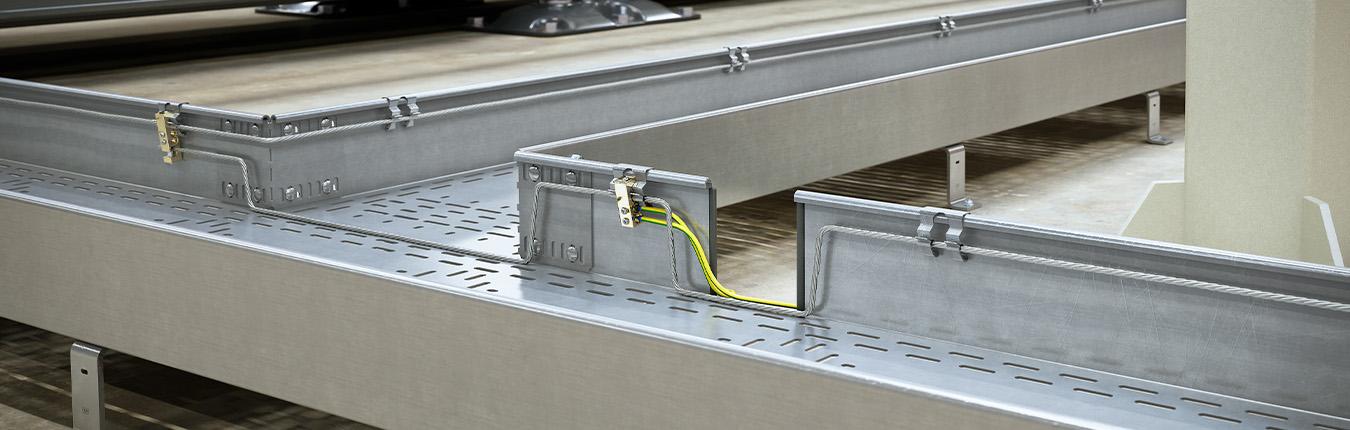

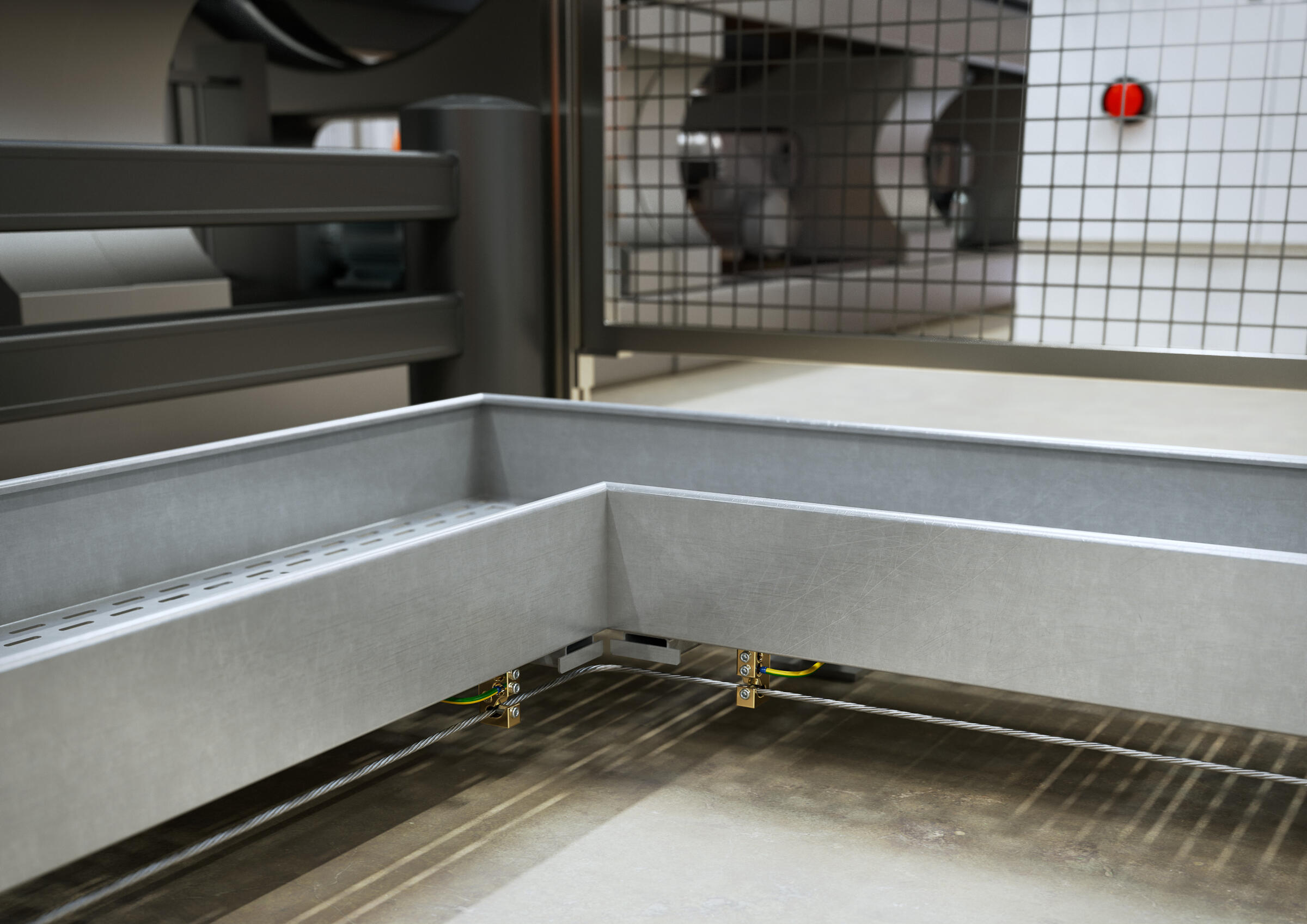

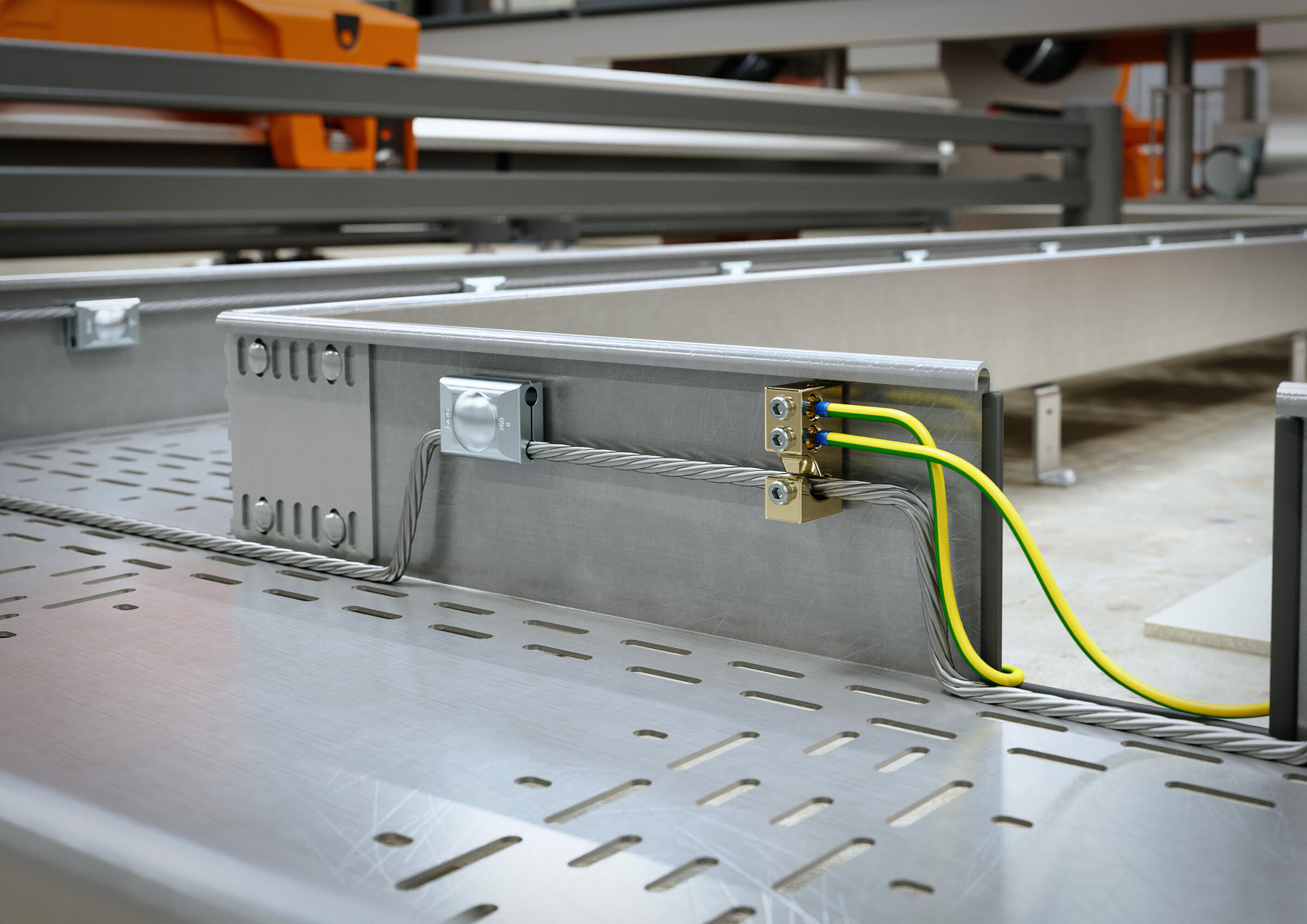

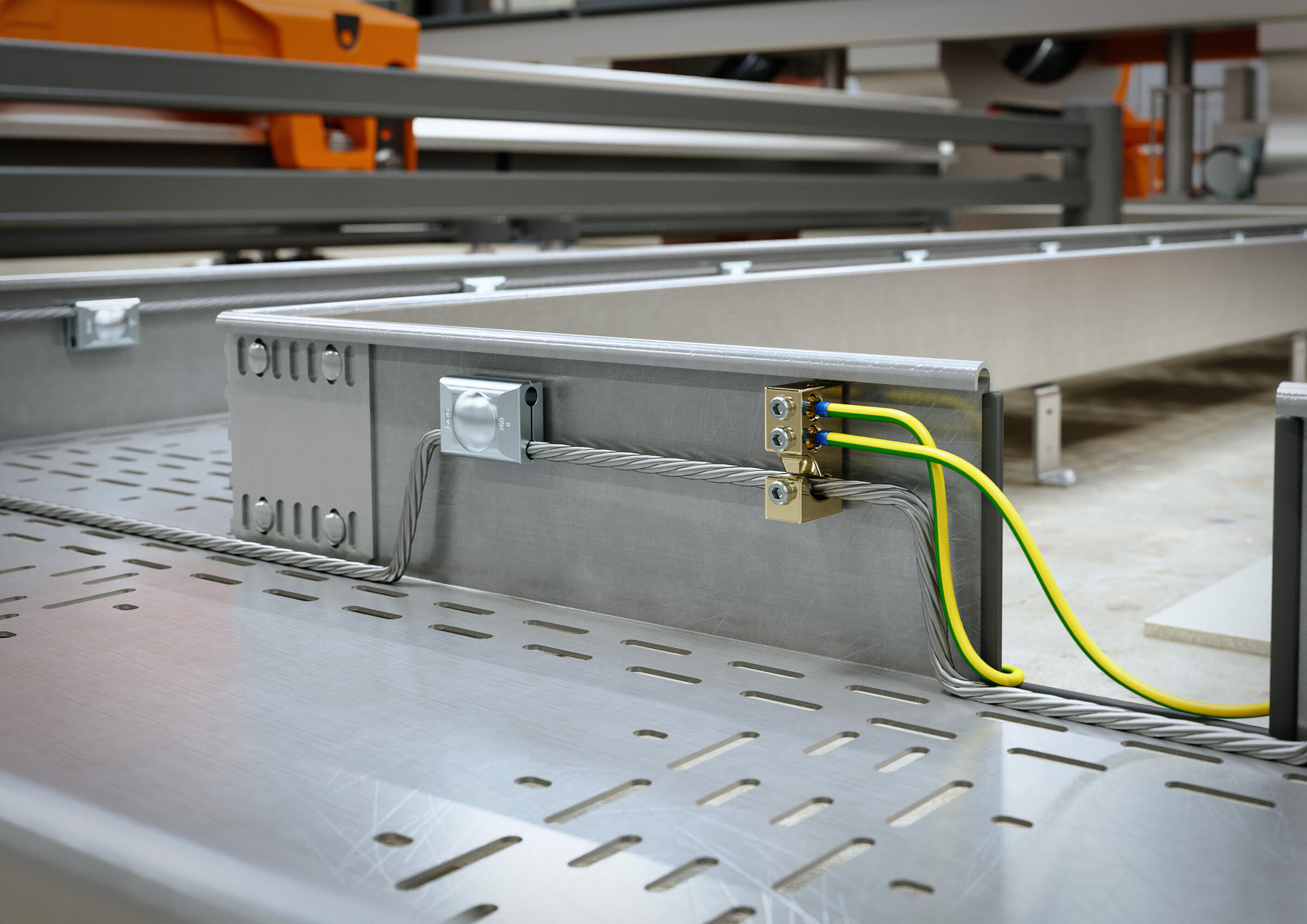

Option 2: Equipotential bonding under the cable tray

In this system, the conductor cable is guided under the cable tray using connection terminals. Tin-plated copper cables in accordance with DIN VDE 0295 Class 2, multi-wire and tin-plated conductor cables according to DIN VDE 0295 Class 5, fine-wire and pair-stranded, from 16 mm2 to 35 mm2 can be used. Fastening is done using the OBO connection terminal.

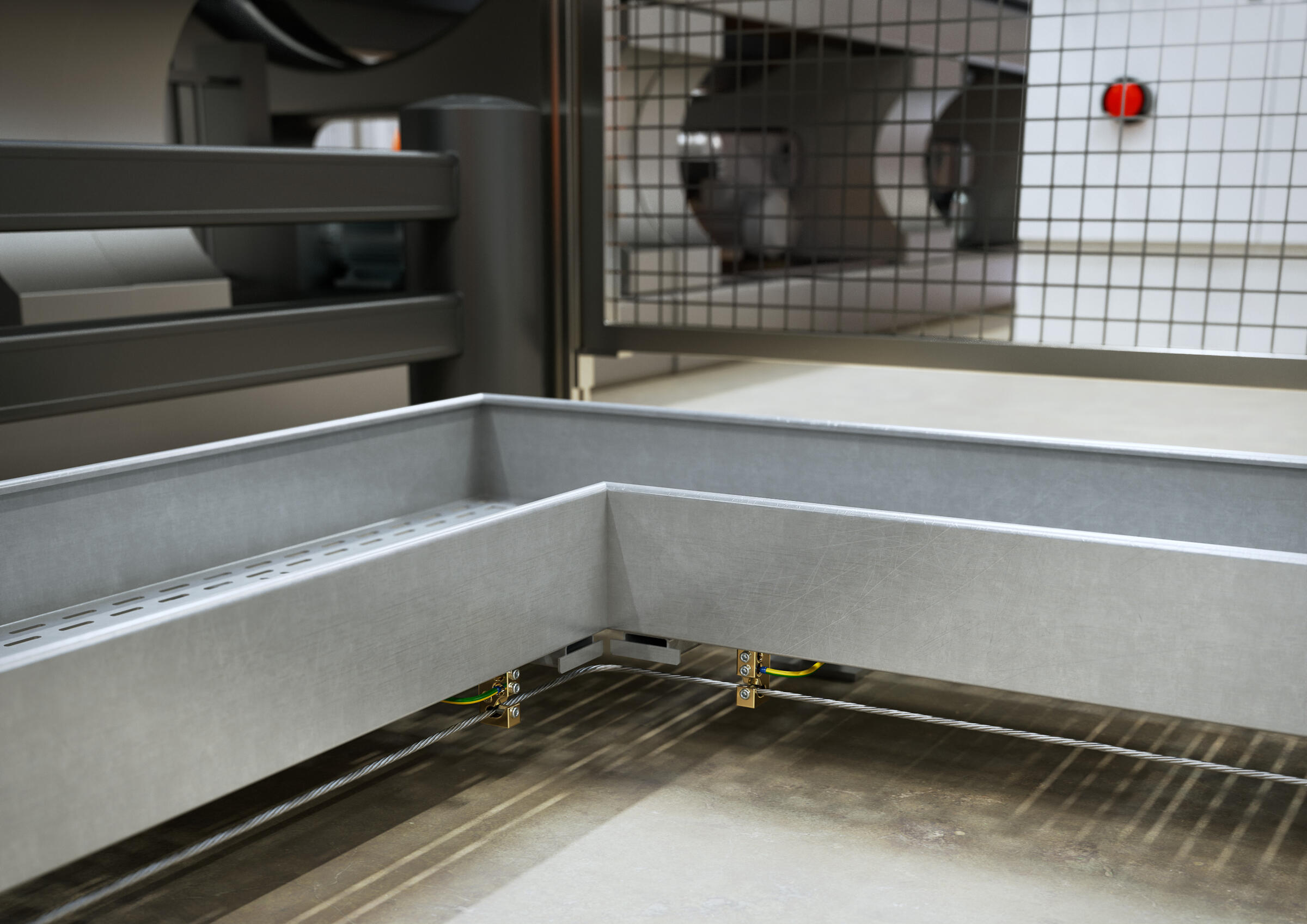

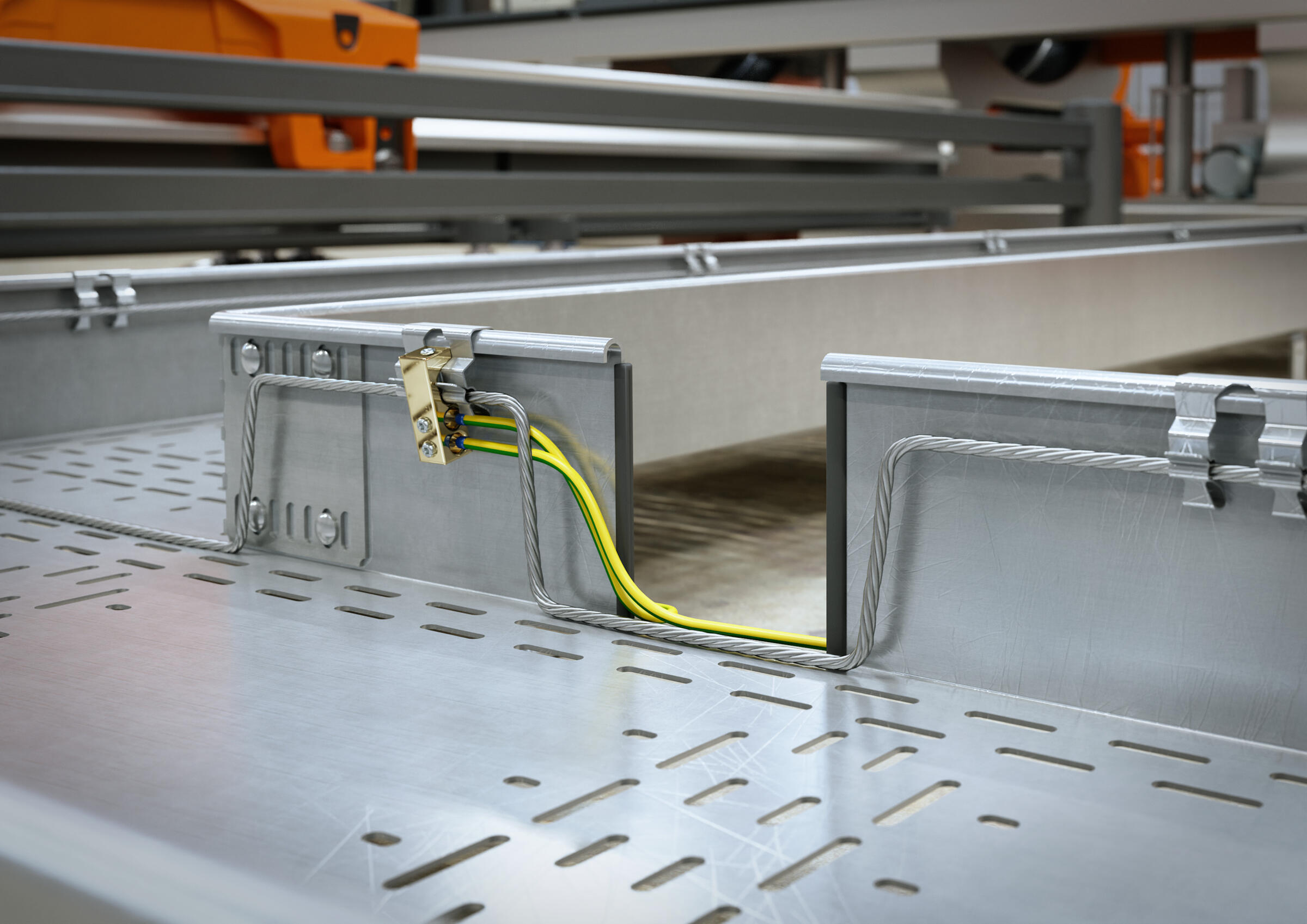

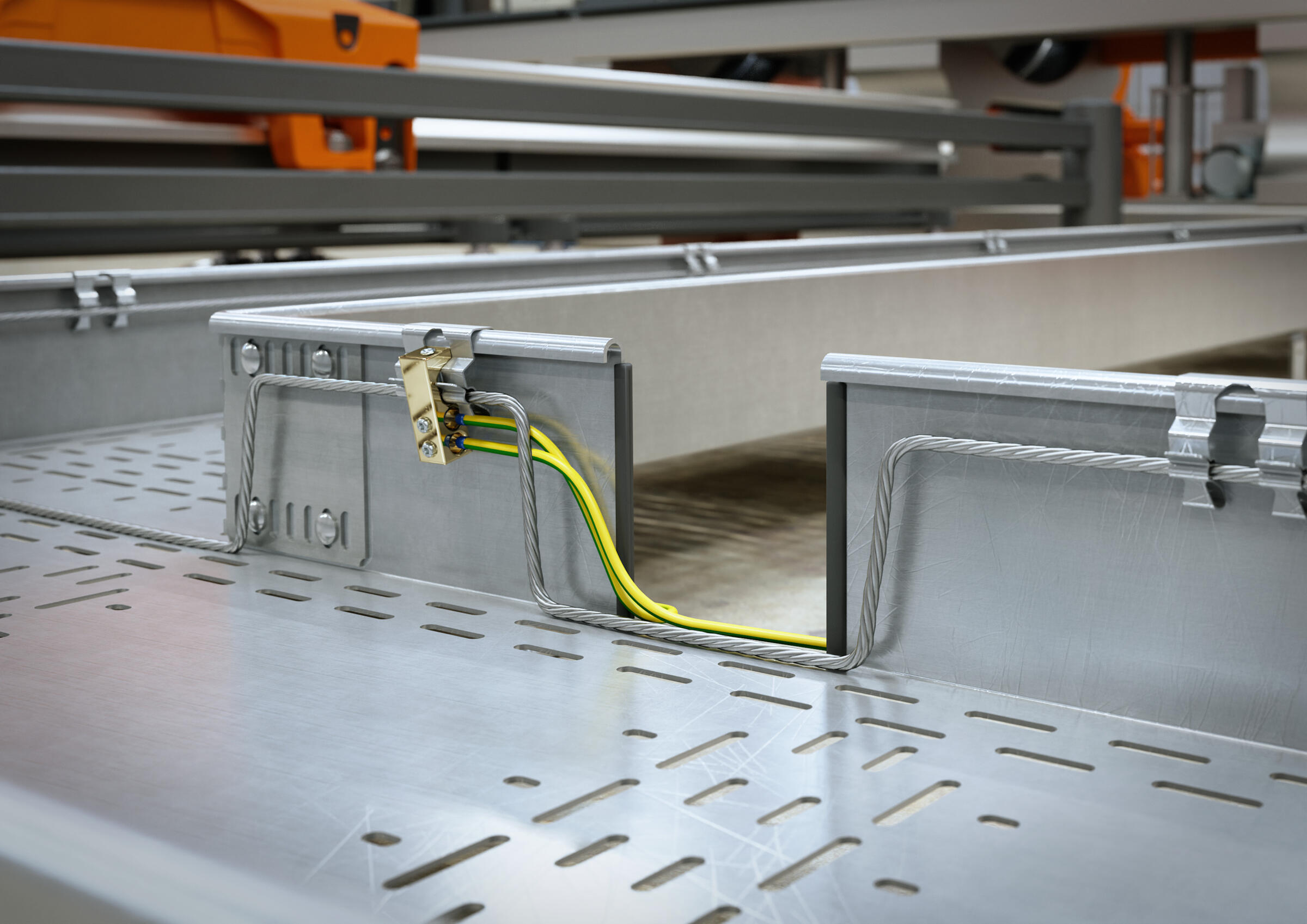

Option 3: Equipotential bonding with central exit

Equipotential bonding is achieved using a 35 mm2 copper cable, tin-plated in accordance with DIN VDE 0295 Class 2. It is routed continuously using parallel connectors. The connection terminal can be mounted anywhere and connected to the conductor cable. It has 2 exits for round conductors up to 35 mm2.

Option 4: Equipotential bonding with flexible branch structure

This system enables structured earthing with flexible branches. Copper cables are supported using special connection terminals and guided via round conductors. The ideal solution for branched earthing grids with different cable cross-sections.

Product highlights

You might also find this interesting

Automotive: Electrical installation in chassis construction

In the automotive sector, OBO concentrates mainly on system construction and conveyor technology. Our focus is on chassis construction.

Slip protection and displacement area

The slip and step protection of the covers is immensely important for safe working on walkable cable trays. The BKRS cover ensures stability and minimises the risk of accidents.

Maximum load-bearing capacity

Heavy loads, footsteps, dirt, dust – the BKRS system can handle all of this and more thanks to its ingenious system design. Cables are protected from damage.

Cover fastening

The cover is fastened quickly and easily, either with a turn buckle or with the cover clamps designed specifically for the chequer plate cover of the BKRS system.

Duct stand-off

OBO is listed by all standard automotive manufacturers. To meet the wide-ranging needs, we offer an approved duct stand-off solution for each of these manufacturers.

EMC protection and dust protection

Modern industrial environments present a major risk to sensitive cables. The BKRS system provides protection, offering an enclosed installation space.

Comprehensive accessories

A wide variety for every requirement: An extensive range of accessories for the BKRS cable trays rounds off the portfolio, offering numerous mounting benefits.