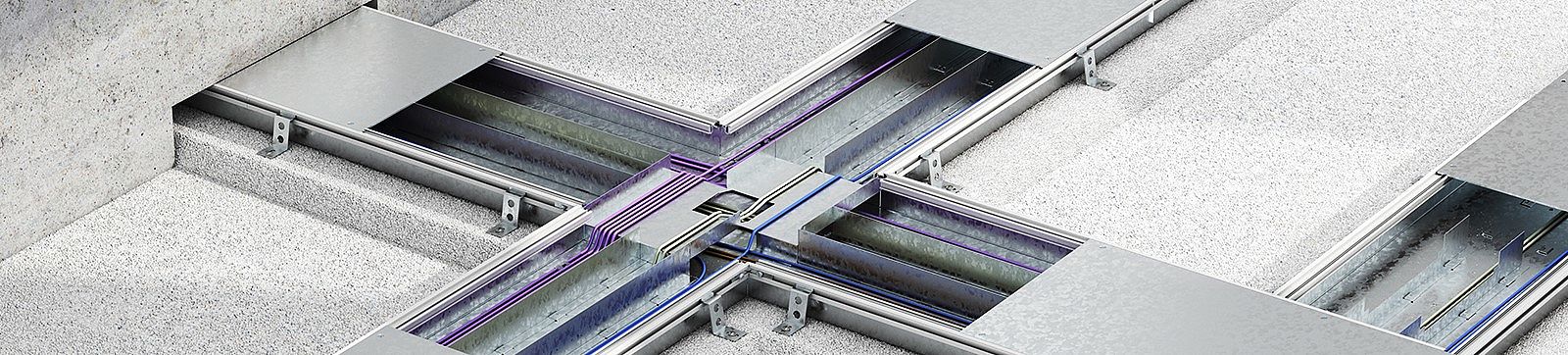

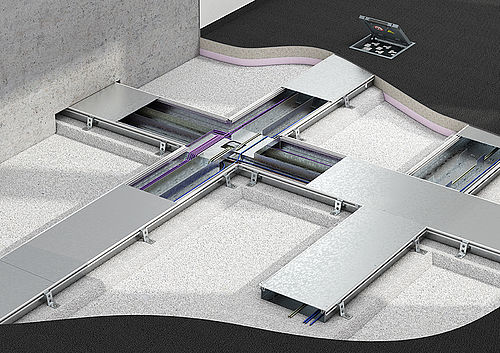

Open screed-flush OKA-T trunking system - flexibility all down the line

The open, screed-flush OKA-T trunking system is used for cable routing and the installation of electrical resources in the underfloor area.

The trunking system is closed on all sides. It can be opened along the entire length.

Secure mounting

The OKA-T trunking system is installed and mounted on the levelled fine layer.

No further levelling is required. The mounting accessories required are included.

Mounting of the trunking covers

The mounting covers are inserted in the side profiles and fastened with the cover fastening screws.

Connection of trunking bases

The trunking bases are aligned by connecting the side profiles. In addition, the screw connection means that the side profiles have a conductive connection and can be included in the protective measure.

Creating equipotential bonding

All the metallic parts of the trunking system must be included in the protective measure against indirect contact with parts carrying voltage and are therefore equipped with the appropriate connection options for the earth conductor clamp.

Fastening the trunking system

Trunking fastening brackets are inserted from the outside into both sides of the side profile.

Pre-mounted units

The trunking units are supplied, ready-to-mount, with three covers. On delivery, the trunking covers are screwed on and strapped on. This means that they cannot get lost on the construction site.

System structure

Cabling

Separating elements ensure safe separation of the cables.

Screed Work

The screed can be laid after the routing, fastening and covering of the trunking system. Ensure that the side profiles are well supported with screed.

Device installation

A service outlet with three partitions is installed in 3-compartment trunking systems. The accessories are mounted in the service outlet in or below type AMPT5 cover plates.