Sustainable production

As a company operating globally, OBO has a great responsibility. We are aware of this and react with sustainable, considerate actions, in order to take care of energy and resources. For us as a manufacturing company, sustainability is especially important in production. This includes product compliance, the use of sustainable materials and material recycling, for example. Other important aspects for us our the circular economy, carbon offsetting and the availability of Environmental Product Declarations for a growing number of our products.

Product compliance

Product compliance describes the sum of the legal obligations a product has to meet. This includes EU regulations, directives and standards. A growing environmental awareness in the industry and in society in general mean that the product requirements are becoming ever more complex.

For us, product compliance is a key component of responsible corporate management. By complying with all applicable directives and safety standards, fulfilling our obligation to label and meeting all regulations on energy efficiency and recycling, we protect consumers and the environment, while also taking another step towards a more sustainable future.

Learn more about our product compliance in our Code of Conduct.

Explanations, certificates and awards

All documents and certificates with regard to sustainability are just a click away – our download area makes it possible.

Recycling and reuse

Material recycling

In the production of wiring trunking and cable duct and trunking, we use the universal plastic PVC, among other things. It goes through a comprehensive external treatment process, where it is ground up separated by type and then fed back into the production cycle. The trunking base of our skirting trunking SL is also made of recycled materials, for example.

Some 90% of the start-up waste and stamping waste can be fed back into the extrusion process as recycled material. A complex recycling method, along with the corresponding plant systems, ensures that the material quality of the 1,600 tonnes of PVC recycled material produced each year stays the same.

That’s not the only benefit – at the same time, energy is also saved. To be more precise:

- 718 tonnes of oil

- 543 tonnes of gas

- 192 tonnes of coal

This corresponds to a reduction in CO2 emissions of 1,917 tonnes per year.

In the field of plastic injection moulding production, over 42 tonnes of plastic waste in the form of starting and waste parts were reused directly in production. The value is considerably higher in plastic extrusion. It was possible to reuse over 1,200 tonnes of plastic material through the recycling process. By reprocessing waste, we have a lower waste rate, which also contributes to more sustainable production.

Reclaimed material

The are manufactured with 100% green eco-power. A purchased reclaimed material is also used to produce the flush-mounted boxes, with quality remaining at the same high level. Reusing the plastic means OBO flush-mounted boxes contribute significantly to a sustainable material cycle.

The path from waste to reclaimed material

- Companies processing plastic produce industrial waste.

- This industrial waste is not simply disposed of, it is transported to a proper facility for processing.

- The waste is sorted and cleaned. This process results in homogenous plastic waste ready for further processing.

- It is then purchased by companies such as OBO as reclaimed material and processed into flush-mounted boxes, for example. Regenerates are a special type of recycled materials that are obtained by melting down and regranulating plastic waste, which are different from simple recycled material due to additives to improve properties.

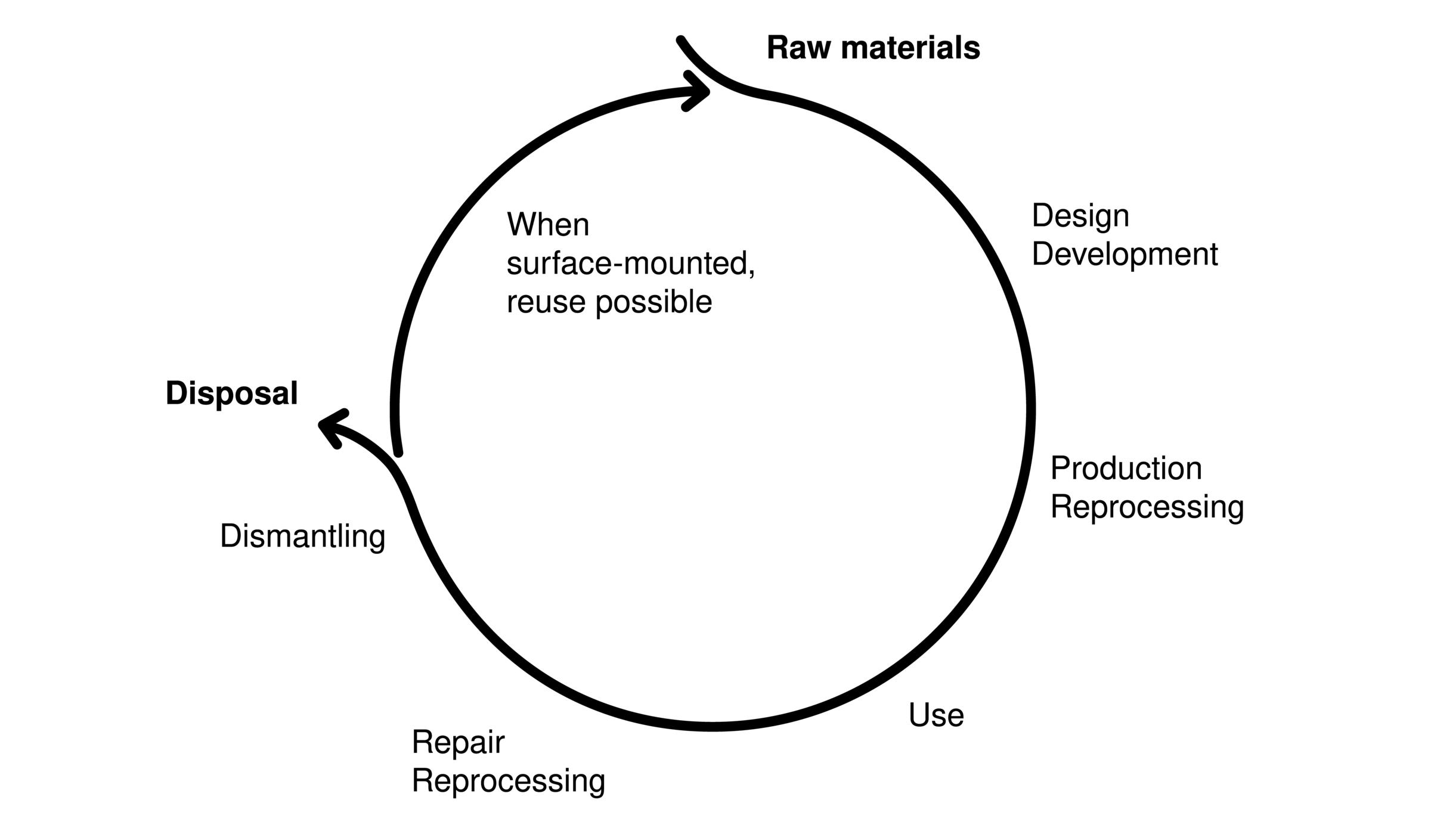

Circular economy

The circular economy is currently a hot topic in the construction industry. The holistic approach begins in the planning phase, where the focus is placed on efficient utilisation of resources. The goal is to minimise waste and protect the environment. The aim is to create long-lasting, adaptable constructions that meet a wide range of requirements. The installed products should be able to be reused. Recycling and using materials over the long term reduces the ecological footprint in the construction industry. OBO does its part with circular products, such as BlackLine , our premium portfolio for black surface-mounted installations. Because all BlackLine products are durable and characterised by high-quality materials and surfaces. When it comes to building repurposing, they are ideally suited to being dismantled and reinstalled for the next application. Surface-mounted installations in particular can be replaced and updated without requiring major work.

DGNB Navigator

Since its foundation in 2007, DGNB has been committed to buildings of proven good quality, liveable districts and a sustainable built environment.

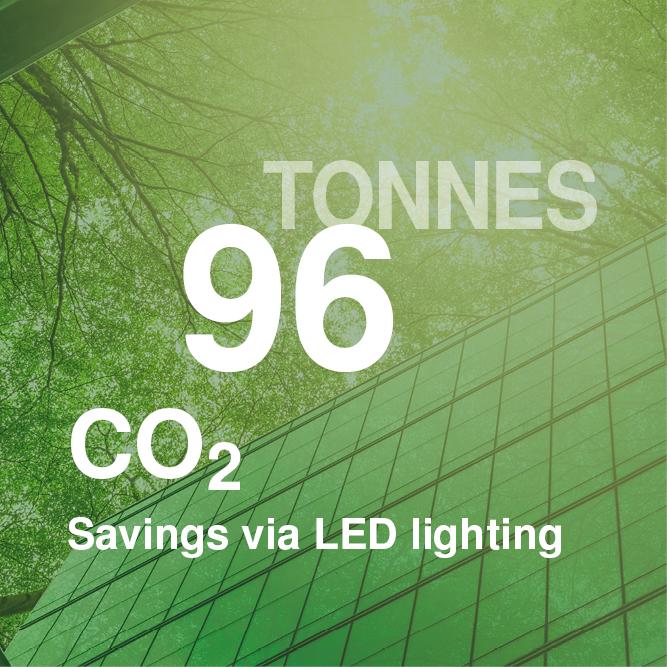

Carbon offsetting

Information on the environmental effects of products can be determined, for example, using a product’s carbon footprint, also known as the Product Carbon Footprint (PCF). The carbon footprint includes the sum of all greenhouse gas emissions of a product over its entire life cycle (cradle to grave). This includes the raw materials used, manufacturing process, transportation, use and disposal. A product’s carbon footprint can be reduced by various measures right at the manufacturing stage, for example through using green energy and sustainable raw materials, increasing the proportion of recycled materials in production or through short delivery routes.

OBO calculates the carbon footprint of more and more products based on the cradle-to-gate principle. This approach – the market standard applied by manufacturers – considers the life cycle of a product from the extraction of raw materials to the point at which the product leaves the factory gate. This allows us to focus specifically on the processes that we can influence and allows us to analyse and optimise their environmental impact.

Today, we are able to provide this information for all OBO products via our online catalogue. This means that we can offer our customers a transparent and reliable information base – similar to the Environmental Product Declarations (EPDs) that include almost all items in our cable support systems and also provide a fact-based information foundation for evaluating product sustainability.

Classified OBO products in the EGH

We at OBO are one of the few manufacturers capable of providing extensive data on sustainability – for each product. Besides the carbon footprint, this includes information on the relevant sustainable ISO standards, such as 14001 or 50001, proportions of sustainable raw or recycled materials, sustainable packaging, existing EPDs and much more. We can provide this information to wholesalers via BMEcat, Open Datacheck or in any desired format.

This is why we are already part of the “Green Offer” programme from Sonepar, and many of our products bear the “alexgreen” label from Alexander Bürkle, which highlights especially sustainable products. The same applies to comparable wholesale shops in other European countries.

Life-cycle assessment parameters and product-related environmental impacts

As a standardised, fact-based source of information for the evaluation of product sustainability, EPDs represent a binding, universally valid basis. Whether architects, planners, engineers, clients, facility managers or auditors ‒ any interested party can use the publicly available EPDs to obtain an overview of eco-balance values and any product-related points of environmental impact.

You might also find this interesting

Sustainability at OBO

With measures that make sensible use of resources at our locations and innovative product solutions, we at OBO think outside the box and act in a sustainable manner.

Social responsibility

We consider ourselves to be a part of society – both regionally and around the world. It is our aim to help shape this society, both now and in the future.

Suppliers

As a globally active company, our supply chains are complex. We place great value on due diligence in human rights and fair business relations.

Our partners

We work with our partners in numerous interest groups and associations, to create a more sustainable future.

Packaging and logistics

With innovative ideas, we have managed to make the transportation, packaging and delivery of our products even more resource-efficient.