Packaging and logistics

With innovative ideas and measures, we have managed to make the transportation, packaging and delivery of our products even more resource-efficient and sustainable. We avoid unnecessary waste, shift transportation from roads to railways and lower our carbon emissions.

Packaging made of recycled material

Eco-friendly packaging material for a more sustainable future

In the field of packaging, we use cardboard made of 100% recycled material as corrugated cardboard or a combination of 98% recycled material and 2% FSC-certified material. As solid board, we already use 100% recycled material.

The film packaging we use is also 100% recycled. The films to protect surfaces represent a greater challenge, which we are currently testing. The majority of our metal products of the cable support system manages completely without or with minimal packaging in the form of plastic tapes. Our cable ladders, cable and mesh cable trays, as well as the corresponding mounting accessories, are packed in recessed pallets and mesh boxes. The recessed pallets and mesh frames are reusable and used multiple times.

With the design of the reusable packaging, for decades we have concentrated on the ability to dismantle them for empty transport, thus allowing space- and resource-saving transport. The loading agents can be repaired and therefore used for years.

Reduced packaging

Thinner wrapping film reduces carbon consumption at the OBO site in Hungary

At our Hungarian site in Bugyi, we have switched our wrapping film used for packaging from a variant with a thickness of 15 µm to a type with a thickness of 12 µm. Wrapping film ensures that packages are reliably protected against humidity, contamination and dust. Pallets loaded with packages are wrapped with the film. This secures and stabilises the packages for transport. Through the shift to a thinner variant with better tensioning properties, we now need significantly less film. This means we will use 3,002 kg less plastic each year for hypothetically the same number of pallets, based on the annual consumption quantities. This means a reduction in emissions of 7,757 kg of CO2 per year.

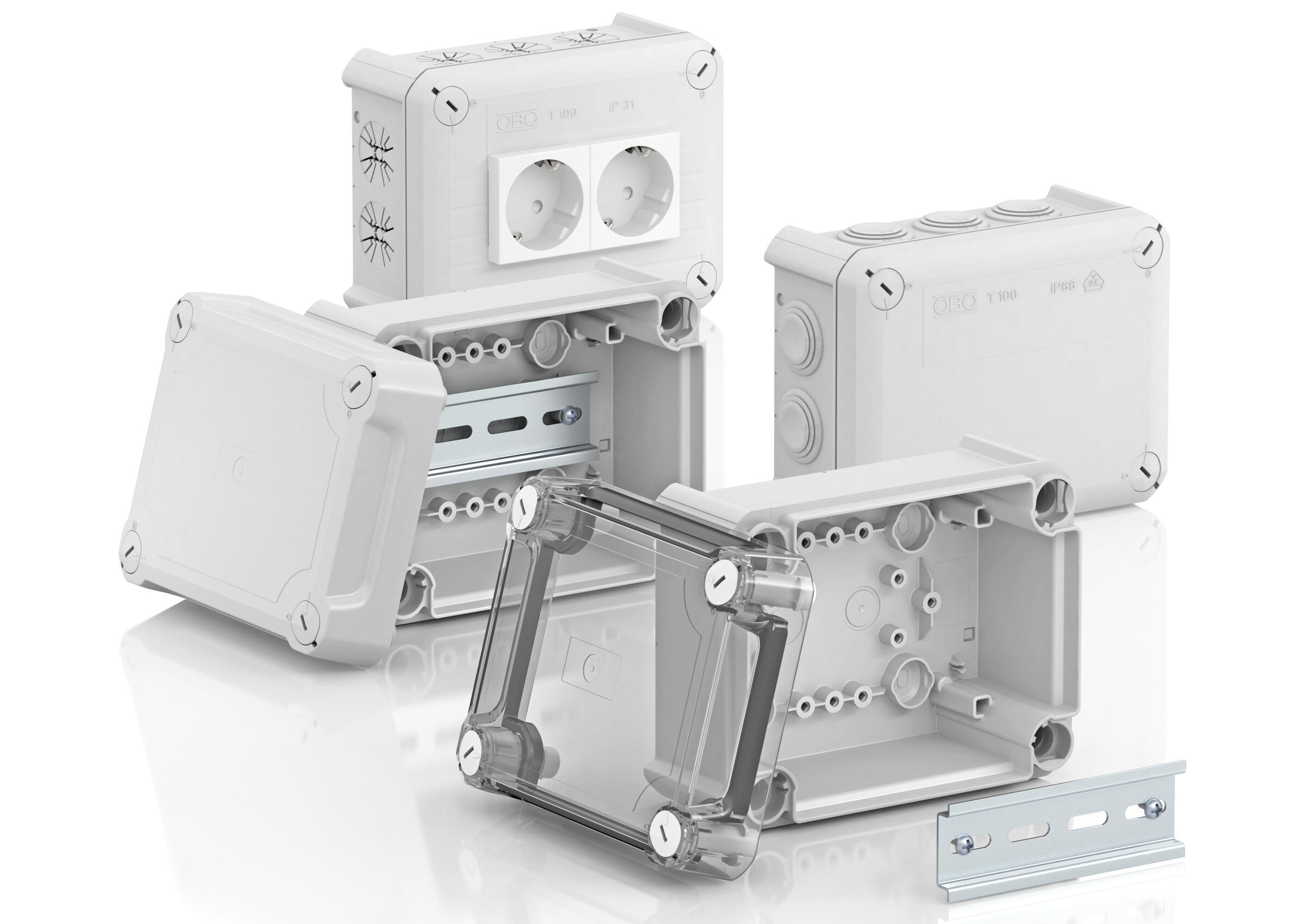

Environmentally friendly packaging solutions for the OBO T series

For the packaging of our junction boxes from the T series we at OBO now rely on eco-friendly packaging solutions. By using sustainable shrink-wrap, we will be able to reduce our annual carbon emissions that result due to the packaging of the T series from 20.7 t to 13.7 t.

At OBO, we are committed to recognising and leveraging potential improvements to conserve resources through intensive tracking and monitoring, as well as continuous improvement. We are proud to have achieved yet another milestone on this journey with our green packaging.

Avoidance of plastic packaging

Sustainable shipping materials

All the shipping materials we use decompose quickly and easily. We use biodegradable shipping pouches for our shipping notes, and our logistics division utilises reusable packaging, cardboard packaging without plastic inlays and filler made of recycled card. For packaging with windows, we use only those made from recycled materials.

Green transport

OBO receives CO2 certificate from LKW WALTER

Just like at OBO, sustainability and environmental protection have been values practised by our partner LKW WALTER for decades. Today, LKW WALTER is one of the leading providers of environmentally friendly transport solutions in Europe. With a CO2 reduction of over 340,000 tonnes per year, LKW WALTER is a good example of how carefully we at OBO select our partners for a sustainable supply chain.

Last year, in cooperation with LKW WALTER, we put 2,541 trucks loaded with OBO products on the road. Some 736 of these trucks were intermodal transports, which is one option for “green transport”. This corresponds to 29% of the volume moved with our partner LKW WALTER. Together with LKW WALTER, OBO Hungary has transported a total of 498 loads, 298 of them in accordance with green transport. That’s 47.8%.

Together for the environment

Among other things, green transport solutions stand for the increased use of transport partners who are driving forward the expansion of combined road and rail transport and are committed to shifting road transport to rail and sea. By using green transport solutions, we were able to reduce CO2 emissions by 671,242 kg in Germany and 224,844 kg in Hungary last year together with LKW WALTER. This is a remarkable amount and a great success on our way to a more sustainable future.

Sustainable logistics

Always keeping an eye on our environmental impact

In Germany alone, we have a volume movement of around 80,000 tonnes per year. We are constantly on the move and our trained specialists in the field of logistics ensure that our products are in the right place at the right time, while always keeping an eye on our environmental impact.

Small measures, big impact in terms of sustainability

By the way, it is not just in delivery and packaging but also in the field of cleaning that OBO logistics are setting a good example, as all the cleaning agents are biodegradable. This is a small change that makes a decisive difference to our environment.

You might also find this interesting

Sustainability at OBO

With measures that make sensible use of resources at our locations and innovative product solutions, we at OBO think outside the box and act in a sustainable manner.

Social responsibility

We consider ourselves to be a part of society – both regionally and around the world. It is our aim to help shape this society, both now and in the future.

Sustainable production

Material recycling and energy-efficient production: Sustainability is becoming increasingly the focus in the production of our products.

Suppliers

As a globally active company, our supply chains are complex. We place great value on due diligence in human rights and fair business relations.

Our partners

We work with our partners in numerous interest groups and associations, to create a more sustainable future.