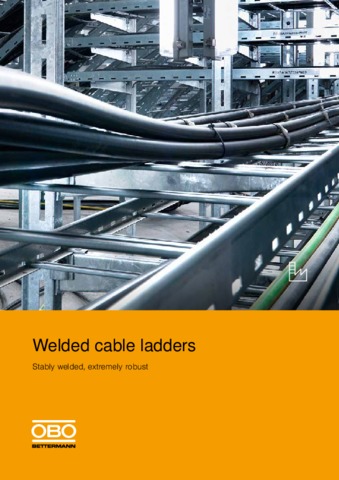

Cable ladder, welded

Welded cable ladders – highly resistant connections

Robustness and easy mounting – for decades, these have been the reliable characteristics of the OBO cable ladders. No matter whether they are riveted, clinched or welded. The cable ladders run for kilometres through industrial plants around the world. One thing is certain: Each individual component is well-thought-out and is securely located.

The new generation of welded cable ladders

OBO has reinvented its tried-and-trusted welded cable ladders and optimised them for use in industry. Thanks to their special design and intelligent rungs, they can offer even more installation space and flexible mounting options – for vertical or horizontal installation.

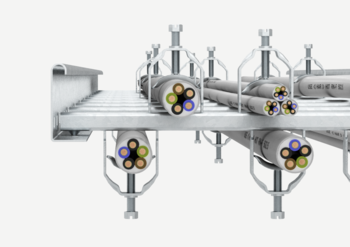

Not only the innovative welding of the new rung, for which a patent has been applied, but its well-thought-out hole pattern are also perfectly tailored to the requirements of all kinds of industrial installations. The special feature: The rungs can be filled on both sides using the matching clamp clips. This means that the installation space can be fully exploited, so that frequently the narrower ladders are sufficient, which reduces costs. The range of materials is not forgotten. The ladders are available in strip galvanised, hot-dip galvanised and A2 and A4 rustproof stainless steel versions. In addition, the new ladders can be powder-coated.

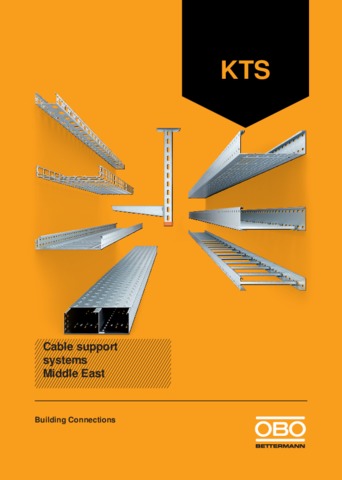

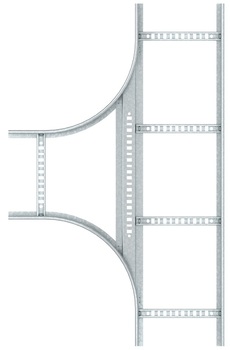

Perfectly matched ‒ the fittings

The fittings of the cable ladder system are the logical addition to the section material. They are also machined with welded rungs and are supplied in the materials and surfaces of the cable ladders.

Easy handling

An optimised standard radius of 300 mm instead of the previous 490 mm makes the fittings more compact and thus easier to handle.

Continuous perforation

Thanks to the innovative rung, the fittings can also be filled on both sides. The continuous perforation allows the use of a wide range of OBO clamp clips.

Extraordinarily flexible

The side rails of the multifunctional connector can be adjusted to any angle and any installation situation, so that both symmetrical and asymmetrical reductions are possible.

Three system radii

The fittings are now available in three system radii. The standard system radius is 300 mm, although 600 and 900 mm radii are also available on request.

- At a glance

- High-resistance rung connection

- Large volume

- Well-thought-out hole pattern

- Practical clamp clips

- Multifunctional connector

- Connector for expansion

- BET-tested

The BET Test Centre

In our in-house BET Test Centre , OBO simulates the loads that the cable ladder systems have to withstand on a constant basis. We determine the maximum load capacity and carrying capacity of the system, as well as its resistance to corrosion. We are able to prove standardised testing of EMC properties using test reports. This means that, as a systems provider, OBO places paramount importance on safety.