Open, screed-flush OKA trunking system

Matches any changeThe OKA system from OBO has proved its worth in practice: It has already been installed in countless buildings. The product developers at OBO have used their practical experience to continuously develop of the system further.

The first open trunking system (OKA for short) was presented as far back as 1974 and, since then, has been continually adapted to installation practices. For more than four decades, planners, architects and customers have relied on the tried-and-trusted technology, primarily for creating a high level of flexibility in electrical installations. The system is beneficial, particularly in the field of large office spaces, as adjustments can be made at any time.

Flexibility all down the line

The OKA open trunking system is a flexible system for in-screed cable routing. The trunking covers can also be opened along the whole length ‒ even when installed with a floor covering. This means that the electrical installation in the floor-flush trunking can be adapted at any time. This means that the system is particularly suitable for users with continually changing requirements for the cable system. Additional mounting benefits, such as lowerable floor covering profiles or rapid height-adjustment units, offer a great deal of flexibility and speed for professional underfloor installations. It is ideally suited for the routing of large volumes of cables, even in low floor structures, and for device installation.

Varied floor coverings

The OKA system from OBO is suitable for all kinds of floor coverings: From carpets through to PVC or linoleum and also for wet-care areas. Through the use of special cassettes, the system can also be equipped for the use of parquet, laminate, tiles or stone floors.

Two variants – one system

The screed-flush trunking of the OKA system is available in two versions: With a flexible side wall and with a closed floor trough. The two variants can be combined easily. The OKA-G variant, with flexible side wall, possesses metal mesh side walls. During mounting, the side walls can be adapted easily to match the substrate and units crossing over. The OKA-W variant, with floor trough, possesses lockable separating retainers, which ensure structure, EMC-compatible cable routing.

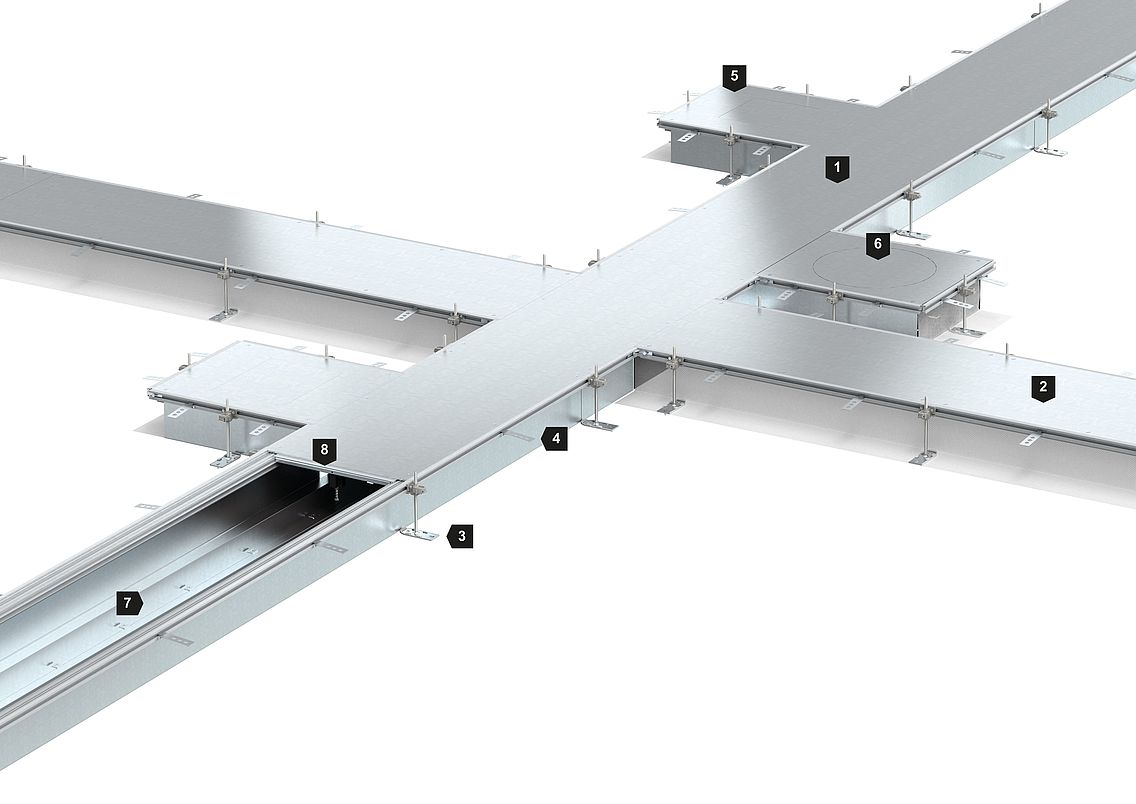

Installation principle

1 | OKA-W installation trunking |

2 | OKA-G installation trunking |

3 | Height-adjustment unit |

4 | Screed tie |

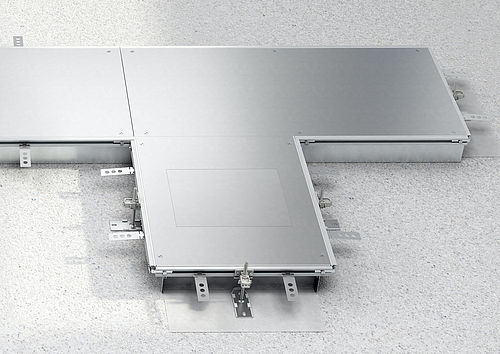

5 | OKA-W extension unit with blank, closed mounting opening |

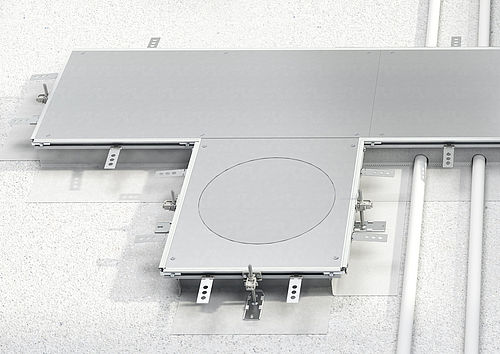

6 | OKA-G extension unit with blank, closed mounting opening |

7 | Separating retainer |

8 | Lid butt support |

Simple and quick installation

The benefits of the OKA system can be seen directly on delivery to the construction site: The partially pre-mounted trunking system ensures quick and simple installation under construction site conditions. The ready-for-mounting cable units are screwed together and their stable construction can withstand all requirements. In so doing, the lids can simply be engaged or screwed to the duct base. With its thick materials, the tried-and-trusted and robust trunking system ensures a safe seat for the floor coverings and traffic loads.